Cement and its concrete products are the second most used products in human society after water. In recent years, cement companies have begun to gradually increase the proportion of alternative fuels in order to reduce production costs, increase environmental protection attributes, and reduce carbon emission intensity. Biomass fuel is an important development direction.

Biomass Alternative Fuel Types and Characteristics

At present, through literature review and research, alternative fuels that can be used in the cement industry include: various crop straws, rice husks, fruit husks, sawdust, cow dung, bamboo chips powder, bagasse, mushroom bags, rapeseed straw, garden waste, wooden packaging boxes, waste paper, etc. Through appropriate pretreatment, it can be prepared into powdered, granular and rod-shaped fuel products for use. The calorific value range is between 2800-4800 kcal, and wood fuel has a higher calorific value. The moisture content is basically 10-20%, the ash content is 5-10%, the volatile content is 65-80%, and the sulfur content is less than 0.15%. The ignition point is basically around 300℃, and the combustion temperature is around 420-460℃.

Biomass fuel has the characteristics of high volatile content, flammability (deflagration), and intolerance to combustion.

Analysis of Key Points in the Use of Biomass Alternative Fuels

1. Replacement rate

Generally speaking, 2-4 tons of biomass fuel can replace one ton of coal. It mainly depends on factors such as biomass fuel type, pretreatment form, technical level, and thermal energy utilization efficiency. Companies with good application of biomass fuel in China have achieved more than 50% replacement of tailing coal and about 30% replacement of total coal.

2. Technical route

In terms of biomass fuel pretreatment, some companies have built their own pretreatment facilities to perform corresponding crushing, screening, drying, mixing and other pretreatments to better adapt to their own factory working conditions; most companies choose to directly outsource finished product production. Material fuels are mostly in the form of granules or rods, and less in the form of powder.

In terms of combustion into the kiln, there are currently three main technical routes: one is direct input into the decomposition furnace; the other is the use of a pre-burner to preheat and dry the biomass fuel for pre-gasification; the third is the coupling of powdered biomass fuel with pulverized coal through coal injection pipe into the decomposition furnace.

3. Adapt measures to local conditions

The selection of biomass fuel needs to be based on actual local conditions. For example, some areas have a large amount of straw, some areas have a large amount of bagasse, and there is a lot of livestock manure in the northern grasslands, etc. At the same time, we must fully consider the seasonal characteristics of biomass fuel and make reasonable storage and use plans.

Southeast Asia Sugarcane Waste Biomass Alternative Fuel Production Project

GEP ECOTECH Biomass Alternative Fuel Processing System

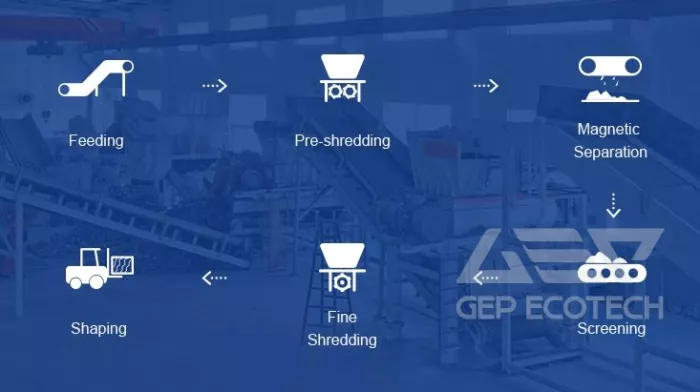

GEP ECOTECH's biomass alternative fuel system realizes fully automated operations from soil removal and impurity removal to shredding and shaping. Through the flexible combination of pre shredders, fine shredders, screening equipment, conveying equipment, pelleting and other equipment, various biomass can be easily converted into alternative fuels for cement plants.

GEP ECOTECH has been focusing on alternative fuel production equipment for many years. If you want to know more about other issues about biomass alternative fuels in cement plants, contact us and let us provide you with professional support.