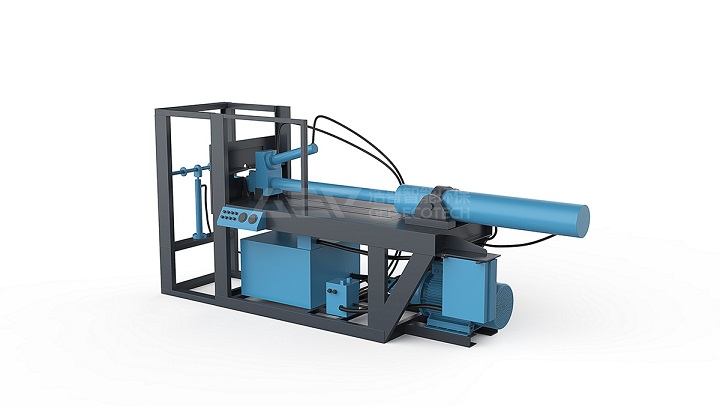

During waste tire recycling, many people know the main machine, double shaft shredder, which can shred the whole tire into small tire strips, but actually there are many other machines are also very important, such as the bead wire pulling machine, it is used to pull out the bead wire of the waste tire which is with diameter more than 800mm.

The working principle of bead wire pulling machine:The basic principle is that the hydraulic system and cylinder are driven by the motor, while the drag hook is connected to the cylinder pull rod. The drag hook do reciprocating motion because of the drive by the oil pump and oil cylinder. Place the tire at the right place, extend the drag hook, start the button when the hook hooks the bead wire. The whole steel wire is pulled out because of the strong pulling force of the oil cylinder, and the side part of the tire is broken to achieve the smooth separation of the bead wire.

The advantages of bead wire pulling machine:

Compact structure, take small area, easy to transport and installation.

Double hook design, the separation efficiency is high, reduce the labour.

The main parts are made ofwear-resisting material and been special disposed, with high strength, resistant to wear and with long working life.

Tire lifting device is equipped that can deal with different size tire, reduce the labour, improve the capacity.

The hydraulic system adopts the international advanced constant power variable piston pump technology, the working noise is low, the pressure is high, the service life of the equipment is improved and the safe operation of the control system is improved.

Manual control the tire lifting and wire pulling, precisely confirm the bead wire to improve the working efficiency.