The RDF plant uses technology to transform sorted solid wasteinto fuel, is usually composed of conveying equipment, shredder, magnetic separators, air separators, fine crusher and RDF pelleting mill.

GEP ECOTECH provided a customized RDF production solution for the first waste-derived fuel (RDF) plant in a Middle Eastern country, deploying multiple RDF preparation units to build an intelligent production line with an annual capacity of 55,000 tons.…

With the promotion of the "dual carbon" goal and the upcoming release of CCER, the demand for energy consuming large households such as power plants, cement plants, and paper mills to replace coal with alternative fuels has become increasingly strong,…

The word RDF is familiar to people in the environmental protection industry, especially in the context of dual-carbon, the surging market demand for alternative fuels and the rise of domestic waste resources, making RDF the outlet of solid waste…

Since President Xi Jinping announced at the 75th session of the United Nations General Assembly on September 22, 2020 that China will strive to peak carbon dioxide emissions by 2030 and strive to achieve carbon neutrality by 2060, the dual-carbon…

An RDF (Refuse-Derived Fuel) line for bulky municipal waste is a specialized waste processing system designed to convert large and non-homogenous waste, typically generated from households and businesses, into a more uniform and energy-rich fuel. This…

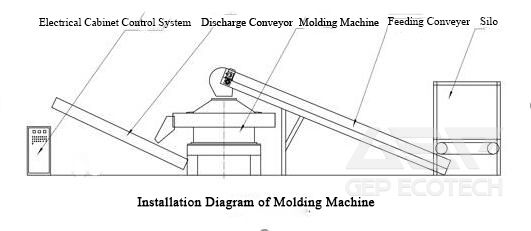

Refuse derived fuel RDF is a fuel made by crushing, sorting, drying, adding chemicals, and compressing combustible waste. In the compression molding process, solid waste molding units are generally used, which include the feeding system, molding system,…

The GPM series RDF forming machine is a solid waste terminal resource utilization equipment developed by GEP, which combines the advantages of similar products. The original design of pressing wheel, module, anti stuffiness machine, full-automatic oil…

The time when the material is extruded in the mold is one of the most important factors in the operating parameters of the RDF forming machine. The length of its forming time depends on the adjustment of the operating parameters of the forming machine,…

The calorific value of RDF(refuse-derived fuels) is a key parameter that affects the energy efficiency and economic benefits of waste-to-energy plants. How to improve the calorific value of RDF in the production process has become a hot topic in the…

The amount of RDF (Refuse-Derived Fuel) that can be produced from one ton of household waste can vary depending on several factors, such as the composition of the waste, the efficiency of the RDF production process, and the technology used for RDF…

Industrial waste is generated in the process of industrial production, which will cause great pollution to the environment if it is not properly disposed of. In recent years, one of the emerging solutions is to make industrial waste into RDF alternative…

RDF production line consists of shredding, sorting system and pelleting system. Firstly, the solid waste is shredded, combustibles are sorted out, and then dried, and finally extruded to make a granular material—RDF.

Recycling of decoration waste is the general trend. Recently, many customers have asked whether decoration waste can be made into RDF? The answer is yes. The high-calorific-value lightweight materials sorted out after the pretreatment of decoration waste…

Solid recovered fuel is prepared from non-hazardous waste and used in incineration plants or collaborative incineration facilities to achieve energy recovery and reuse.At present, the main solid recovery fuel preparation technologies include drying and…

The equipment of this project consists of the third-generation fine shredder, chain conveyor, belt conveyor, magnetic separator, uniform feeder and RDF pellet mill. Through fully automated crushing, sorting and molding processes, industrial solid wastes…

Governments all over the world are faced with how to manage municipal solid waste. Although strengthening recycling technology can reduce a large part of waste, a large part of municipal solid waste is still landfilled. Landfill means waste of resources…