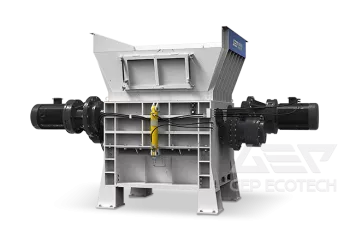

Four shaft shredder is one of GEP's core products in the field of fine shredding. It uses four sets of shear knife rollers to rotate at different speeds to grasp, shear, and tear materials. Its powerful grasping and shearing capabilities not only eliminate the assistance of pressing components, but also achieve high shredding efficiency; the built-in equipment can quickly replace the sieve, which not only facilitates the control of material particle size, but also makes the material particle size more uniform. A single device can meet the particle size requirements of customers, and can produce special effects in various material shredding processes.

Applicable scope

Four shaft shredder has strong shear strength and material adaptability, suitable for various fields such as industrial waste, household waste, medical waste, large waste, hazardous waste mixtures, etc. It is suitable for bucket products (plastic buckets, metal buckets, paint buckets, ibc ton buckets, chemical buckets), plastic products (plastic frames, plastic plates, plastic cans, plastic pallets), metal products (aluminum profiles, oil filters, and cans) the resource utilization of solid waste such as paper (newspapers, cardboard, corrugated paper, copy paper), electronic appliances (refrigerators, circuit boards, tv casings, cd discs), glass products (glass wool, glass cups, glass bottles, fiberglass), and the production of waste derived fuels (rdf/srf) can all demonstrate good processing capabilities.

Operational principle

After the material enters the shredding box, it is torn into small pieces through the tearing and shearing action of the blades on four sets of knife rollers. The discharge size is controlled by the screen. After the material is cut once, the material with a particle size smaller than the sieve mesh hole is discharged from the lower sieve mesh hole of the box under the action of gravity and extrusion pressure. The material with a size larger than the sieve mesh hole is guided by the main cutting knife and auxiliary cutting knife, and returns to the tearing box along the inner surface of the sieve mesh for secondary cutting. This cycle is repeated until the material can be discharged from the sieve mesh hole.

Common troubleshooting

Fault Phenomenon | Failure Cause | Troubleshooting |

Equipment no work | 1. Power supply voltage too high or too low 2. Broken wire, connector and terminal falling off 3. “Emergency Stop” button pressed 4. Main power supply not connected 5. Thermal relay disconnected due to overload 6. Overload protection current set too low 7. The fuse blown | 1. Check whether the voltage is normal 2. Repair the broken wire and connect and fasten the terminal correctly 3. Open the “Emergency Stop” button 4. Check whether the main power supply is connected 5. Reset the thermal relay 6. Reset the overload current value 7. Replace the fuse |

Too fast cutter wear | 1. Poor cutter material 2. Too many hard objects in the materials 3. Material handled not suitable for the shredder | 1. Adopt original cutters or replace with high-quality cutters 2. Add auxiliary device to remove hard objects 3. Material cannot be processed |

Abnormal noise | 1. Check whether the metal is put into the feed hopper by mistake 2. Check whether the bearing is damaged 3. Movable cutters touch fixed cutter plates 4. Abnormal noise due to loose parts | 1. Stop the equipment and remove hard metal objects 2. Stop the equipment and replace the bearing 3. Adjust the distance between movable cutters and fixed cutter plates 4. Adjust loose parts and re-lock them |

Shutdown | Equipment overload shutdown | Remove the materials in the equipment, manually start the reverse rotation, and then start the forward rotation(forward rotation start with load strictly prohibited) |