Recycling waste tires into rubber powder is relatively complicated, and usually requires crushing, wire separation, granulation, grinding, fiber separation and other processes to make rubber powder of different finenesses. Below are the key machines in the process:

Tire Shredder

- Breaks whole tires into rubber chips (50–100 mm).

- Durable blades and optional screening ensure uniform output.

Steel Wire Separator

Removes steel reinforcements from rubber chips using magnetic separation.

Roller Screen

- Separates materials by size, ensuring only properly shredded chips move to the next stage.

- Improves efficiency and prevents overloading downstream equipment.

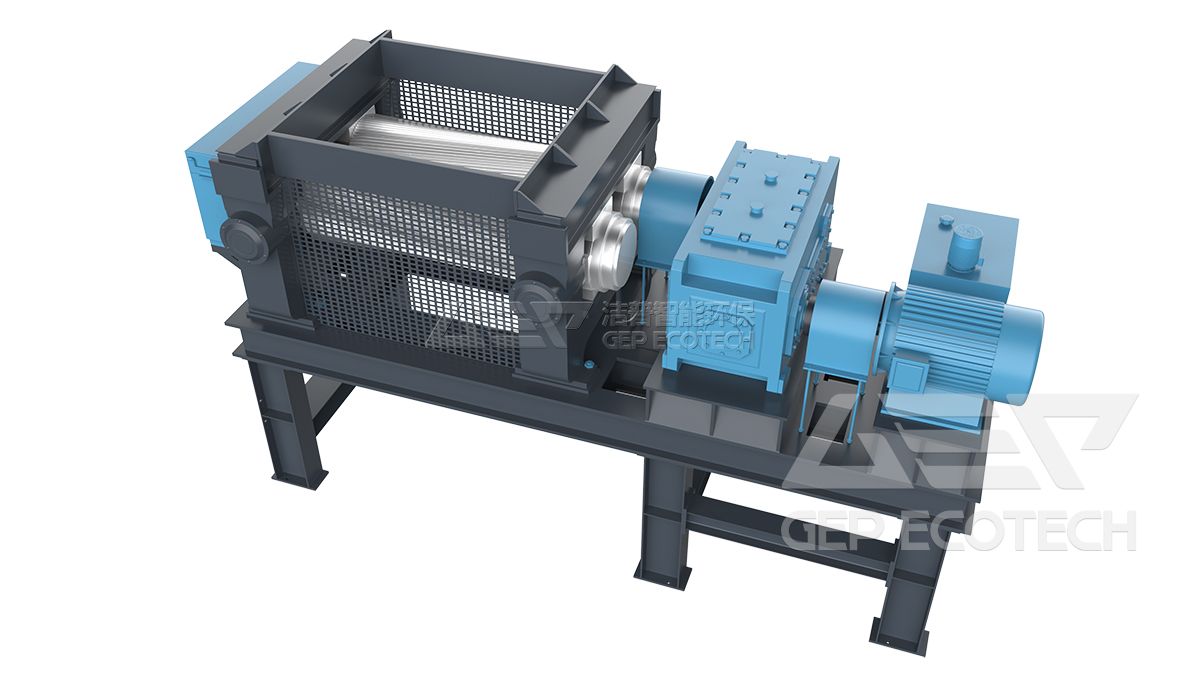

Granulator

- Reduces rubber chips into granules (1–5 mm).

- High-speed blades for precise sizing.

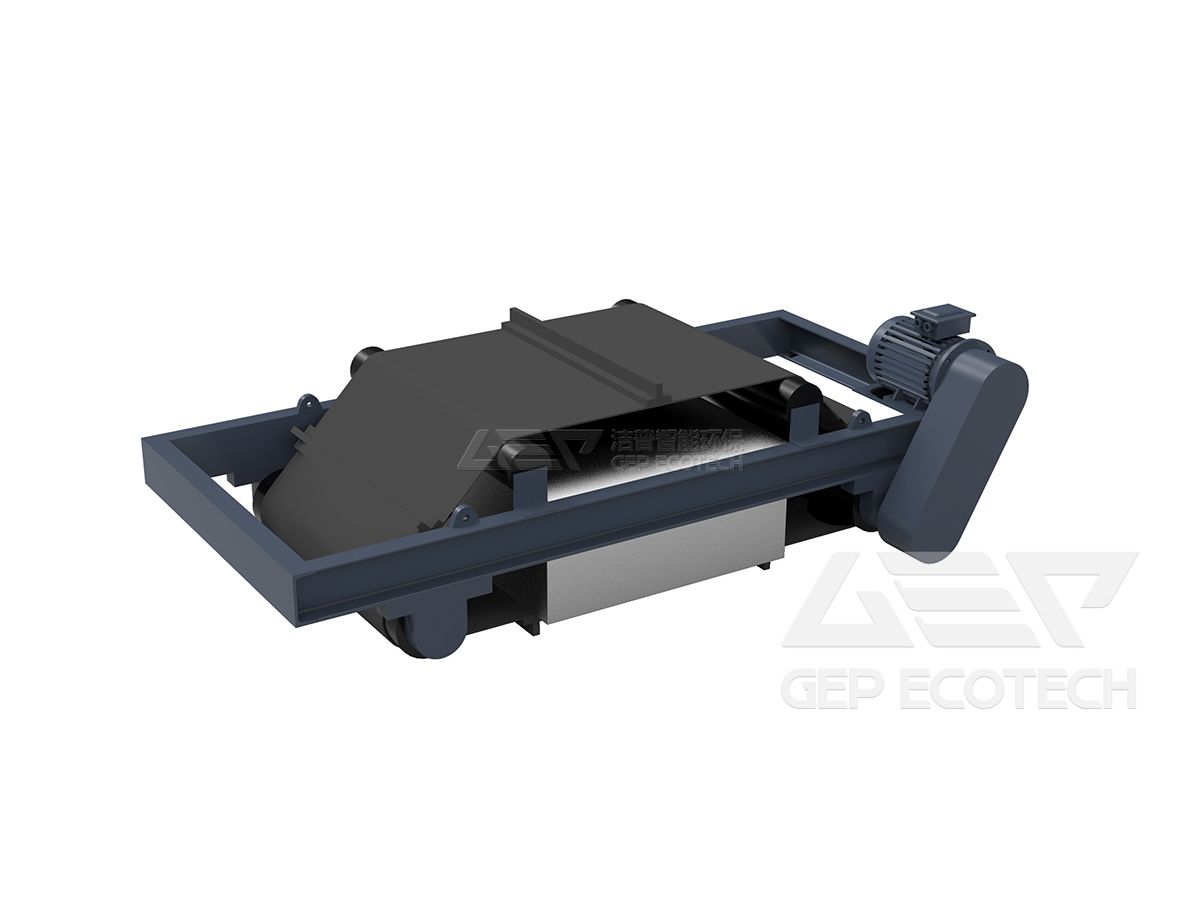

Magnetic Separator

- Removes any remaining metal particles from rubber granules.

- Ensures the final product is free from metallic contaminants.

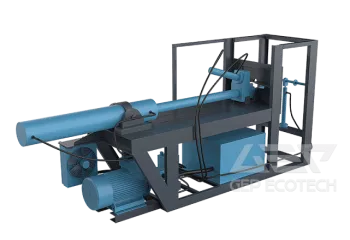

Rubber Grinder

- Processes granules into fine rubber powder (10–120 mesh).

- Equipped with cooling and dust control systems.

Fiber Separator

Removes residual tire fibers from the rubber powder.

Conveyor Systems

Transports materials between machines for seamless operation.

A complete tire powder production line ensures effective recycling, supporting sustainable waste management. Contact us for tailored solutions!