Petroleum coke, or pet coke, is a carbonaceous solid derived from oil refinery coker units or other cracking processes. It serves as a valuable fuel source in various industries, including cement, power generation, and metallurgy.

To efficiently process pet coke, specialized equipment known as crushers is required. The crusher can effectively break large pieces of petroleum coke to the required particle size. This not only improves the efficiency of subsequent processes such as grinding and activation, but also facilitates storage and transportation. In this article, we will explore the different types of equipment suitable for petroleum coke crushing and their key characteristics.

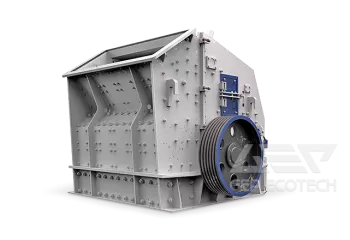

Impact Crusher

One commonly used type of equipment for crushing petroleum coke is the impact crusher. Impact crushers utilize high-speed impact forces to break the material into smaller particles. They feature a rotating rotor with rigid hammers or blow bars that strike the pet coke as it enters the crushing chamber. Impact crushers are known for their high reduction ratios and ability to produce uniform-sized particles.

Hammer Crusher

Another option for crushing petroleum coke is the hammer crusher. Hammer crushers consist of a series of hammers mounted on a rotating shaft. The pet coke is fed into the crushing chamber, where the hammers repeatedly impact and crush the material against a breaker plate. Hammer crushers are versatile machines capable of handling a wide range of materials and are suitable for both primary and secondary crushing.

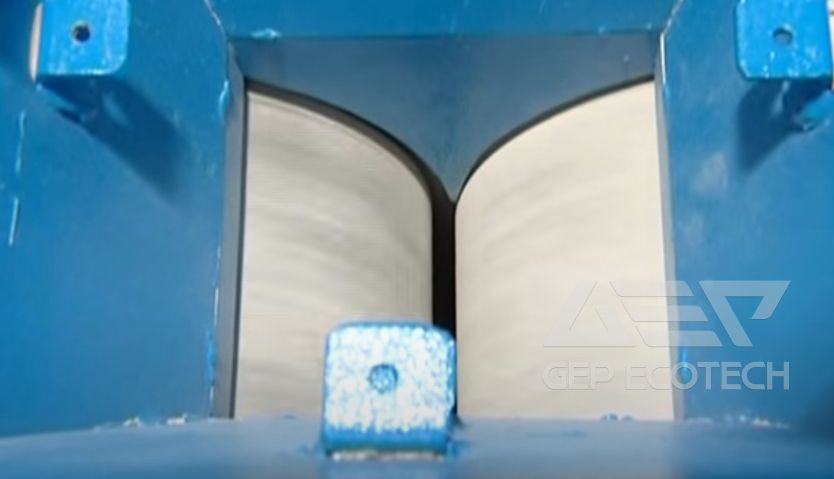

Roll Crusher

Roll crushers are also commonly used for crushing petroleum coke. These crushers feature two parallel rolls rotating in opposite directions. The pet coke is fed between the rolls, where it is crushed and compacted by the compression forces exerted by the rolls. Roll crushers are known for their ability to produce finely crushed material with minimal fines generation.

Selection Considerations

When choosing the right equipment for petroleum coke crushing, several factors should be considered:

- Feed Size: The size of the pet coke feed material will influence the type and size of the crusher required.

- Capacity Requirements: Determine the desired throughput capacity of the crusher to ensure it meets production needs.

- Particle Size Distribution: Consider the desired particle size distribution of the crushed material and select a crusher that can achieve the desired specifications.

- Material Properties: Evaluate the abrasiveness and moisture content of the pet coke to ensure the selected crusher can handle the specific characteristics of the material.

- Maintenance and Operating Costs: Assess the maintenance requirements and operating costs associated with each type of crusher to determine the most cost-effective option.

Selecting the right equipment for petroleum coke crushing is essential for achieving efficient and reliable processing. Impact crushers, hammer crushers, and roll crushers are all viable options, each offering unique advantages depending on the specific application requirements. By carefully considering factors such as feed size, capacity, and maintenance costs, operators can choose the most suitable crusher for their pet coke crushing needs.