Converting scrap metal material to a specific size for further processing requires intelligent shredding solutions. The addition of a shredder to the sheet metal recycling process reduces worker risks associated with manual handling, feeding and cutting of sheet metal material, further automating the production line. The dual shaft shredder is designed with a low speed, high torque cutter to reduce sparking and easily shred thin metals such as sheet iron for further processing and handling. Reducing material size also increases scrap density per bin, resulting in reduce costs associated with waste transportation. Since the double-shaft shredder is so suitable for crushing iron sheets, how much does a double-shaft shredder for iron sheets cost?

Many factors can affect the price of a metal sheet twin shaft shredder. For example, there are iron sheet double-shaft shredders of different sizes on the market. Some shredders can produce more than 60 tons per hour, and some shredders can produce hundreds of kilograms per hour or less. The difference in output will result in a difference in the price of the equipment. So what other factors affect the price of equipment? Mainly in the following aspects.

Factors affecting the price of iron sheet double shaft shredder

- Material situation

- Processing yield

- Outlet requirements

Knowing the above basic requirements, a company's sales manager can quote the approximate equipment price for your reference, but remember, in addition to the above factors, equipment materials, brand strength, and after-sales service are also important factors that affect the price. If you want to ensure the healthy and stable operation of the equipment, you must consider it comprehensively before making a choice. For example, GDI iron sheet double shaft shredder is a good choice after comprehensive consideration, let us see why we choose it to shred thin metals such as iron sheet.

GDI iron sheet double shaft shredder performance characteristics

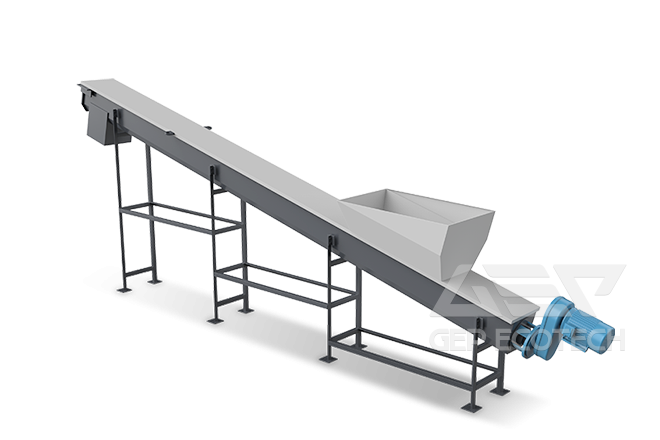

GDI double shaft shredder is a double shaft shearing shredder. The double shaft shearing shredder has the advantages of large torque, high output and wide applicability of materials. It can tear, cut and extrude scrap iron sheets into smaller granularity, which is convenient for subsequent processing.

GI intelligent monitoring system

Through the real-time monitoring and analysis of the overall operation data of the production line, the GI intelligent monitoring system can timely understand the operation status of the equipment and reduce the cost caused by errors.

Customized design, all models

GDI iron sheet double shaft shredder can be customized with different models, different output, high crushing efficiency, single machine production capacity can reach 60t/h, which can meet the crushing requirements of different customers.

Quality Parts Configuration

GDI iron sheet double shaft shredder adopts high-quality bearings and multiple sealing technology; advanced anti-loosening technology can avoid equipment failure due to loose bolts; it is equipped with high-quality electrical components and has good controllability.

High-precision machining technology

All key components of the GDI sheet metal twin-shaft shredder are made of high-quality alloy forgings. After heat treatment, the wear resistance is good, the strength is high, and the service life is increased by 3-5 times; the overall knife box design, the frame structure is firm, and the strength is greater.

GDI iron sheet double shaft shredder has helped many customers to solve the problem of thin metal accumulation, and striving for profit space for customers is the product design standard we keep in mind. After years of continuous optimization, GDI has become one of the best-selling products in the market. If you have scrap metal or other solid waste that needs to be disposed of, please contact us for more professional support!