Demolition waste refers to the discarded materials or wastes generated by residents and business units in the process of renovating and decorating their houses, including concrete, mortar, bricks and tiles, ceramics, stone, gypsum, aerated concrete blocks, metal, timber, glass, paper, fabrics, and plastics.

Instead of being hastily buried or torched, these so-called "wastes" can be given a "twist of fate" by carefully designed process systems: concrete waste, Ceramics can be used as road base material for road construction; bricks, tiles and stone can be used as raw material for sintered bricks; gypsum can be used as filler; aerated concrete blocks can be used to make wall materials or thermal insulation; metals can be smelted back into recycled metals; wood can be used to make new furniture and wood products; and combustible lightweight materials, such as paper, fabric and plastics, can be processed into alternative fuels with high heat.

This is the demolition waste disposal process that GEP designed for a client :

After fully considering factors such as operational efficiency and operational energy costs, we have designed a process route of "screening before crushing, more screening and less crushing", in which a number of screening equipment and crusher are jointly operated, so as to reduce complex and diversified renovation wastes step by step, Reduce and purify the waste step by step, and the customers finally get the pure aggregates of various particle sizes they want. It really achieves the efficiency, effect, and benefit, all three effects are good.

Some discerning customers have also focused their investments on lightweight materials from demolition waste, which are currently the "hot" raw material for alternative fuels, the magic weapon for carbon reduction. GEP will not disappoint its customers, and this lightweight alternative fuel preparation process is already in use at many sites:

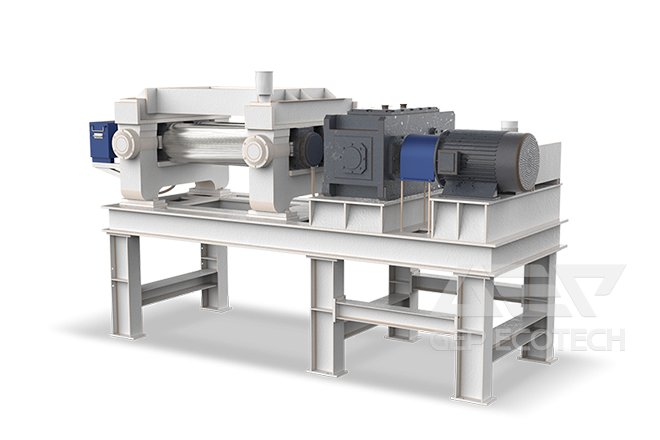

After these light materials are disposed of through Pre-crushing, magnetic separation, and fine crushing, they are alternative fuels that can be sold directly. The back-end RDF moulder or hydraulic baler will meet the storage and transport requirements by changing the shape of the alternative fuel.

Of course, this process needs to be differentiated for different project needs and material characteristics. Equipment such as tumbler screen and wind separator will be selected from our rich product library according to the actual needs and re-optimized to form a suitable process solution.

Overall, the disposal and utilization of demolition waste is a complex and challenging issue. However, through scientific design and rational process systems, these wastes can be "turned around" and turned into valuable resources that can bring more benefits to our society and the environment. This is the core concept of GEP's approach to demolition waste disposal, and it is also our goal to create value for our customers. In the future, we look forward to working with more partners to promote the resourceful use of demolition waste and make greater contributions to building a better environment.