Carbon black is produced by decomposing rubber through thermal decomposition or hot pressing. The main source of raw materials is waste tires. One ton of waste tires can be pyrolyzed to obtain 0.35 tons of carbon black. In recent years, due to rising coal prices and pressure to reduce dual-carbon emissions, many cement companies have begun to use rubber cracking carbon black as an alternative fuel.

Characteristics of Carbon Black Alternative Fuel for Cement Plants

- Pyrolytic carbon black has low volatile matter, which can reduce the amount of combustion exhaust gas and reduce system power consumption after use;

- Pyrolytic carbon black has high combustion intensity and concentrated heat release, which is beneficial to the decomposition of limestone and has high energy utilization efficiency;

- The price of pyrolytic carbon black is lower than coal, and it has good economic, social and environmental benefits as an alternative fuel.

Production Equipment of Carbon Black Alternative Fuel for Cement Plants

The production equipment for alternative fuel carbon black in cement plants usually includes the following main components:

1. Waste tire pretreatment equipment:

- Tire Cutter: Used to cut waste tires into small pieces or pieces for subsequent processing.

- Tire Shredder: further crushes the cut waste tire blocks or pieces into smaller particles to facilitate subsequent processing.

2. Waste tire pyrolysis or gasification equipment:

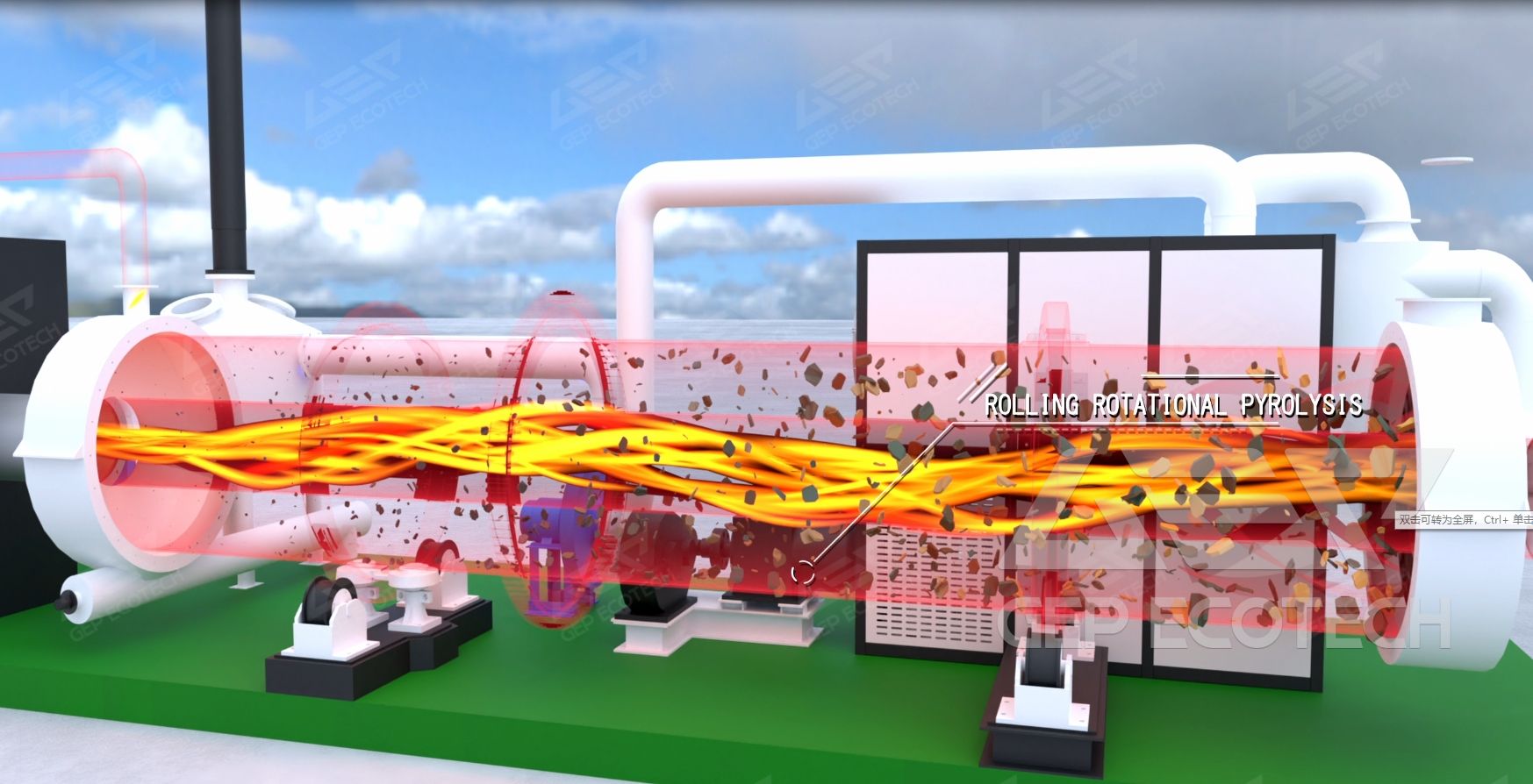

Pyrolysis Reactor or Gasification Reactor: Pyrolysis or gasification of waste tire particles in a high-temperature environment to decompose organic matter in the tires and generate carbon black, liquid fuel and gaseous products.

3. Carbon black separation and collection equipment:

- Cyclone Separator: Used to separate carbon black and other solid particles from the gas stream.

- Filter: further purifies the gas flow, removes residual fine particles, and ensures the quality of the collected carbon black.

The adoption of carbon black as an alternative fuel in cement plants necessitates the deployment of specialized production equipment to convert waste materials into a viable energy source. By investing in efficient pyrolysis or gasification technologies and robust emission control systems, cement plants can enhance operational sustainability, reduce environmental footprint, and contribute to the circular economy by repurposing waste tires for energy generation.