If you're investing in Refuse-Derived Fuel (RDF) production technology, this isn't just a question—it's one of the most critical factors determining your operation's profitability and efficiency. The short answer is a definitive yes.

At GEP ECOTECH, we don't just support customization. We consider it a fundamental principle of our product design and engineering philosophy. A one-size-fits-all approach is ineffective in waste management. Your feedstock is unique, your output goals are specific, and your machinery should be meticulously engineered to match.

Why Custom Mold Design is Non-negotiable in Modern RDF System?

The mold is the heart of your RDF Pellet Mill. It's where loose, flaky SRF/RDF material is transformed into a dense, high-calorific-value fuel pellet. The dimensions of this mold—specifically its inner diameter and length—directly influence:

Pellet Density & Calorific Value

A larger diameter might require higher pressure to achieve the core density needed for optimal burning. Custom sizing ensures the perfect pressure-to-volume ratio for maximum BTU output.

Production Throughput

Longer molds can sometimes allow for higher production rates, but only if the system and power unit are designed to support it. Customization balances mold size with overall system capacity.

Pellet Density & Calorific Value

A larger diameter might require higher pressure to achieve the core density needed for optimal burning. Custom sizing ensures the perfect pressure-to-volume ratio for maximum BTU output.

Production Throughput

Longer molds can sometimes allow for higher production rates, but only if the hydraulic system and power unit are designed to support it. Customization balances mold size with overall system capacity.

Material Compatibility

The composition of your waste stream (e.g., high plastic content, high fibrous material, mixed industrial waste) affects how it compresses. A mold tailored to your material's friction and compaction characteristics prevents jamming and ensures smooth operation.

End-User Requirements

Cement kilns, power plants, and other off-takers often have specific preferences for briquette size to fit their feeding systems and combustion chambers. Custom molds let you produce the exact product your market demands.

Our Engineering-Led Approach to Custom Mold Design

How do we ensure your custom mold delivers peak performance? It's a process rooted in deep research and development, not just simple machining.

Phase 1: Collaborative Analysis

Our engineers work with you to understand:

Your raw material analysis (composition, moisture content, calorific value).

Your target briquette density and final dimensions.

Your desired hourly production capacity.

The capabilities of your existing upstream equipment (shredders, classifiers, etc.).

Phase 2: Advanced Simulation & Modeling

Leveraging technology and softwares, we simulate the extreme pressures and thermal stresses within the proposed mold design. This allows us to:

Predict wear patterns and identify potential failure points before manufacturing.

Optimize the mold's internal geometry and taper for efficient material flow and ejection.

Select the perfect grade of alloy steel (e.g., HD550 tool steel) and specify specialized heat treatment processes for unparalleled abrasion resistance and longevity.

Phase 3: Precision Manufacturing & Integration

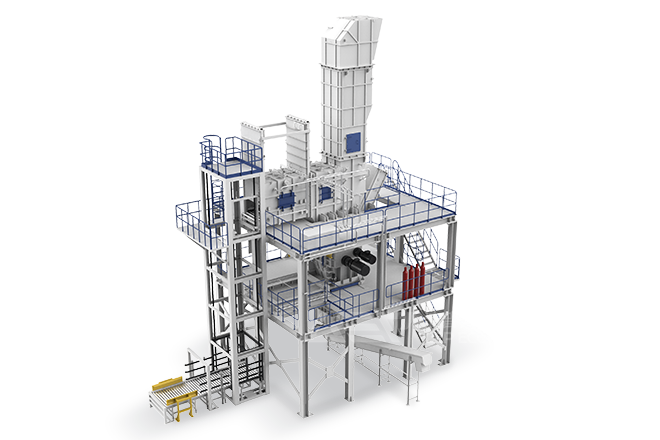

Our molds are CNC-machined to microscopic tolerances. A perfectly smooth, precisely honed internal surface is critical to reduce friction, lower power consumption, and prevent material sticking. The mold isn't developed in isolation; it's engineered as a core component of the entire press system, ensuring perfect harmony with the hydraulic power pack, PLC controls, and feeder system.

Phase 4: Continuous Support and Optimization

Customization doesn't end at delivery. We provide tailored advice on maintenance schedules and keep a record of your specific mold specifications for fast replacement or future optimization needs.

An RDF Pellet Mill perfectly tuned to your operation produces higher-quality fuel, faster, and with less energy, maximizing your return on investment (ROI).

Let's maximize ROI and engineer your perfect RDF System solution together!