As an important component of renewable energy, biomass energy plays a crucial role in promoting energy transition. The Guiding Opinions point out that we should steadily develop biomass power generation, promote the transformation of biomass combustion technology for large-scale coal-fired power generation boilers to co burn agricultural and forestry waste, and encourage the use of biomass pellet fuel stoves for heating in remote areas.

From a policy perspective, the application of biomass energy is mainly concentrated in the fields of biomass direct combustion power generation, biomass coupled coal power generation, and biomass formed fuel. GEP ECOTECH has proposed multiple intelligent system solutions for these three major application directions, which have achieved significant results in improving energy efficiency, reducing operating costs, and enhancing equipment stability.

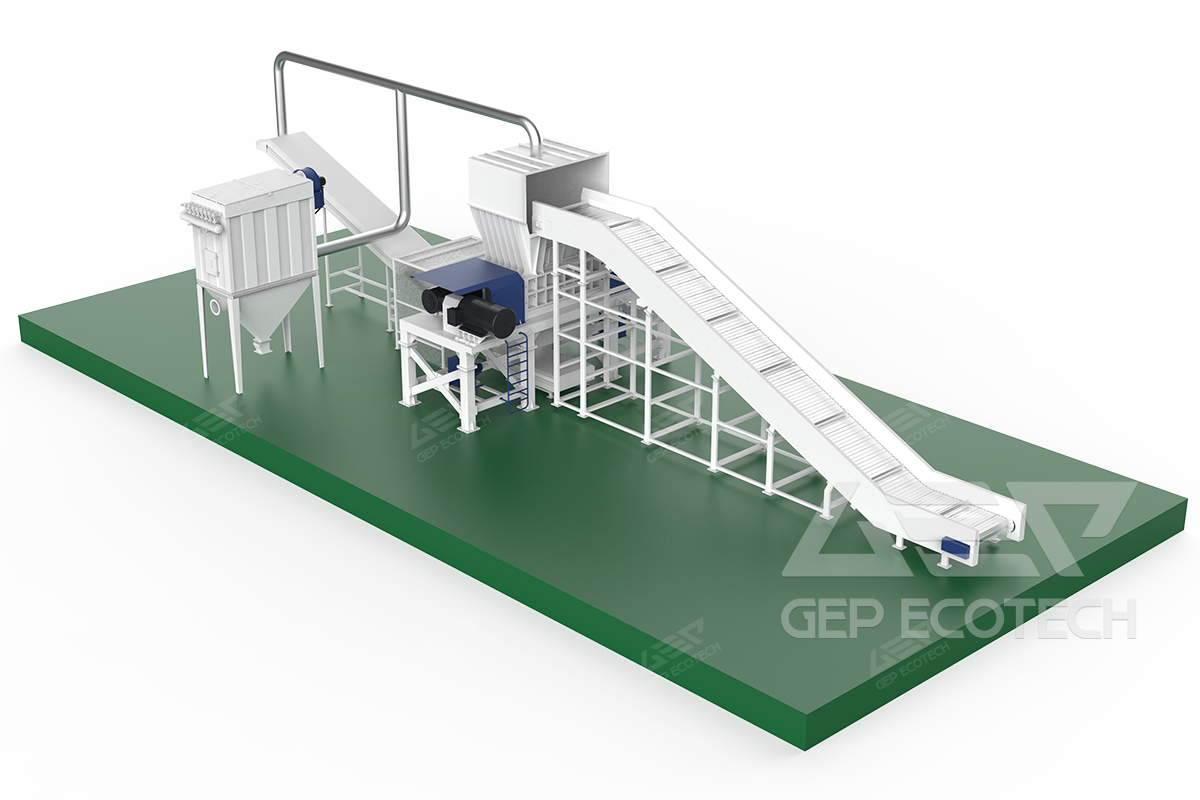

Pre Treatment Scheme For Biomass Direct Combustion Power Generation

Biomass direct combustion power generation is currently one of the most widely used forms. GEP ECOTECH's solution ensures that biomass raw materials meet the feeding requirements of direct fired power generation boilers through pre-treatment processes such as shredding and iron removal. After pretreatment, biomass raw materials not only have higher combustion efficiency, but also effectively reduce equipment wear, thereby achieving a reduction in power generation costs and long-term stable operation of the power generation system.

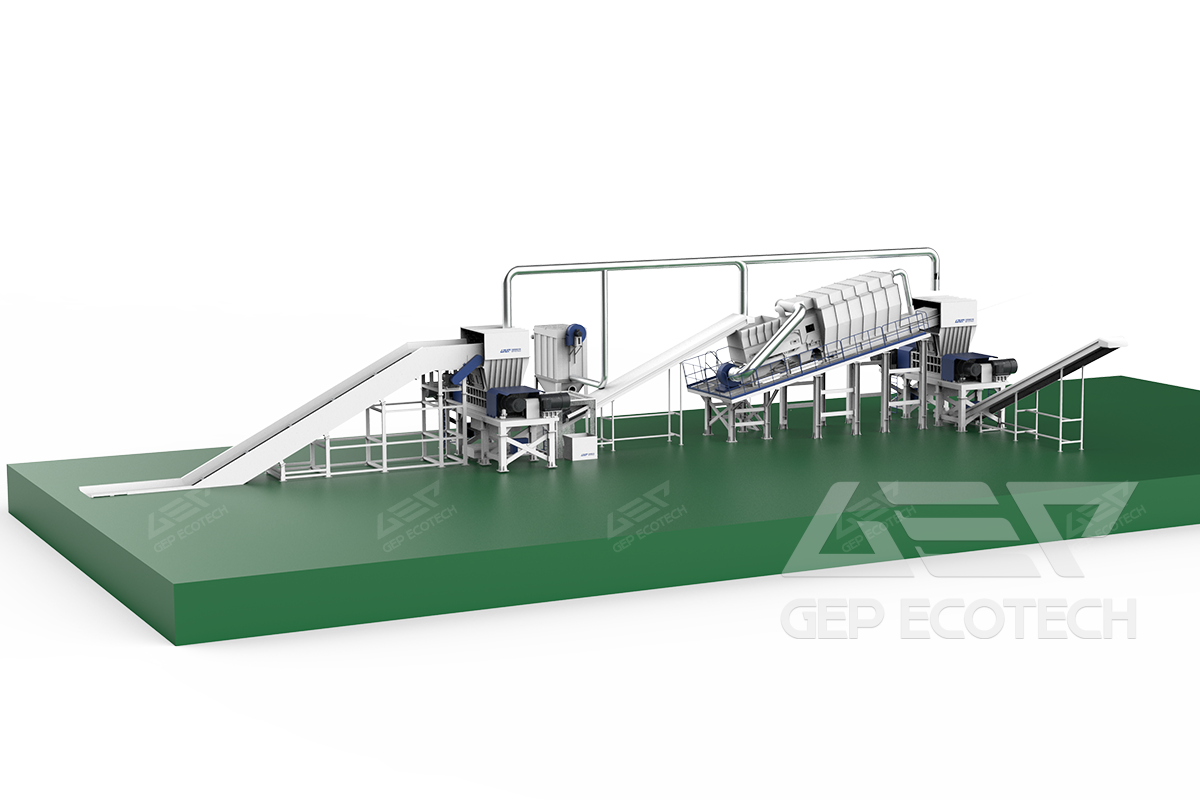

Pre Treatment Scheme For Biomass Coupled Power Generation

In the field of biomass coupled coal power generation, GEP ECOTECH provides two pre-treatment solutions for different needs. The first solution is to use a biomass fine shredder with a built-in adjustable screen in the fine shredding process, which can flexibly control the particle size of the discharged material and adapt to different process requirements; The second option uses two different specifications of dual axis shredders, each responsible for coarse and fine shredding tasks, to ensure that the discharge size meets the standard requirements of coupled power generation.

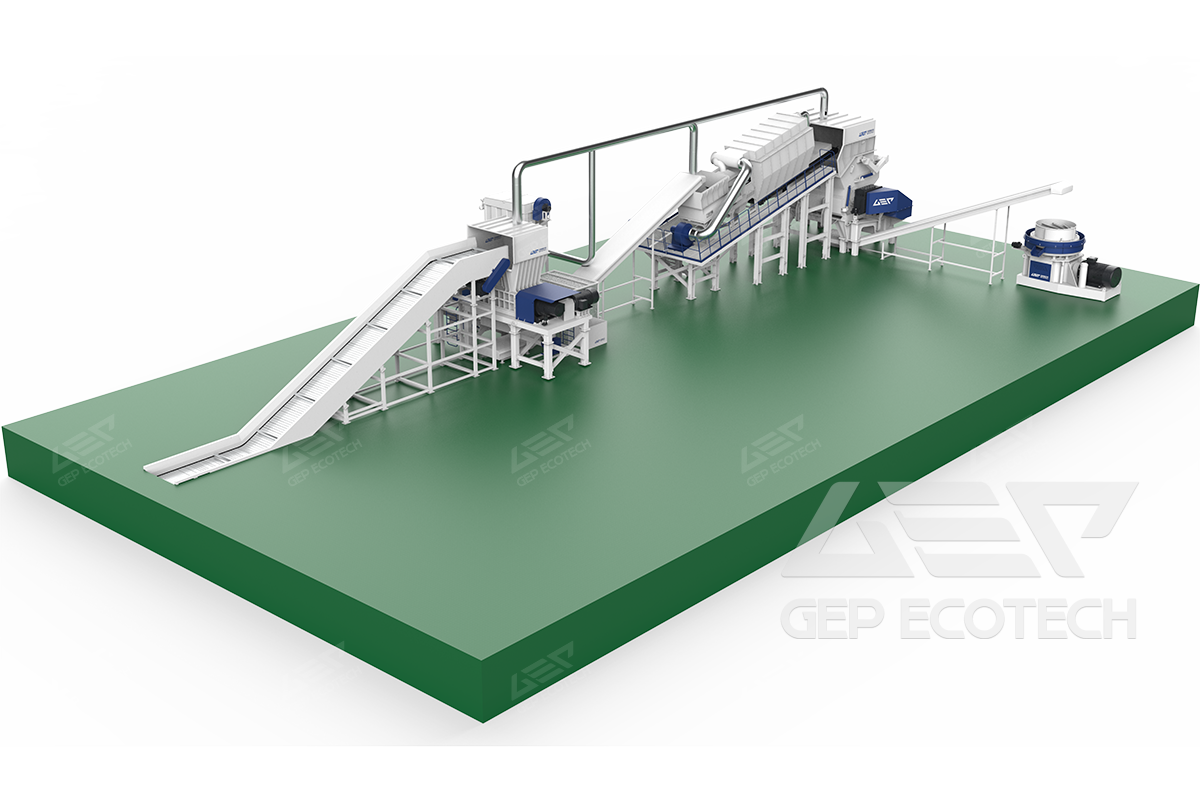

Preparation Plan For Biomass Pelleting Fuel

GEP ECOTECH also has strong technical support in the preparation of biomass based fuels. Through the combined application of dual axis shredders, biomass shredders, magnetic separators, sorting systems, and RDF pelleting machines, agricultural and forestry waste can be converted into small volume, high density, high purity, and high calorific value forming fuels, which are widely used in fields such as power generation and heating.

GEP ECOTECH's biomass energy solution deeply integrates modern intelligent technology. Through an intelligent monitoring system, the equipment status is monitored in real-time, alarms are issued in a timely manner, and automatic oil lubrication is achieved, significantly reducing energy consumption, improving production efficiency, and reducing equipment downtime due to malfunctions. The automatic adjustment function of the chain plate conveyor, the excellent shredding ability of the double axis shredder, and the precise separation ability of the sorting system have comprehensively improved the stability and operational reliability of the overall system.

GEP ECOTECH's biomass energy solutions will become an effective weapon for various enterprises to address challenges such as carbon emissions, energy structure transformation, and cost pressures.