In the rapidly evolving world of metal recycling and waste management, the development of specialized equipment like the two-shaft aluminum shredder marks a significant advancement. This machine is specifically designed to handle the unique challenges posed by aluminum waste, which is prevalent in various industries and consumer products.

Design and Functionality of Two-Shaft Aluminum Shredders

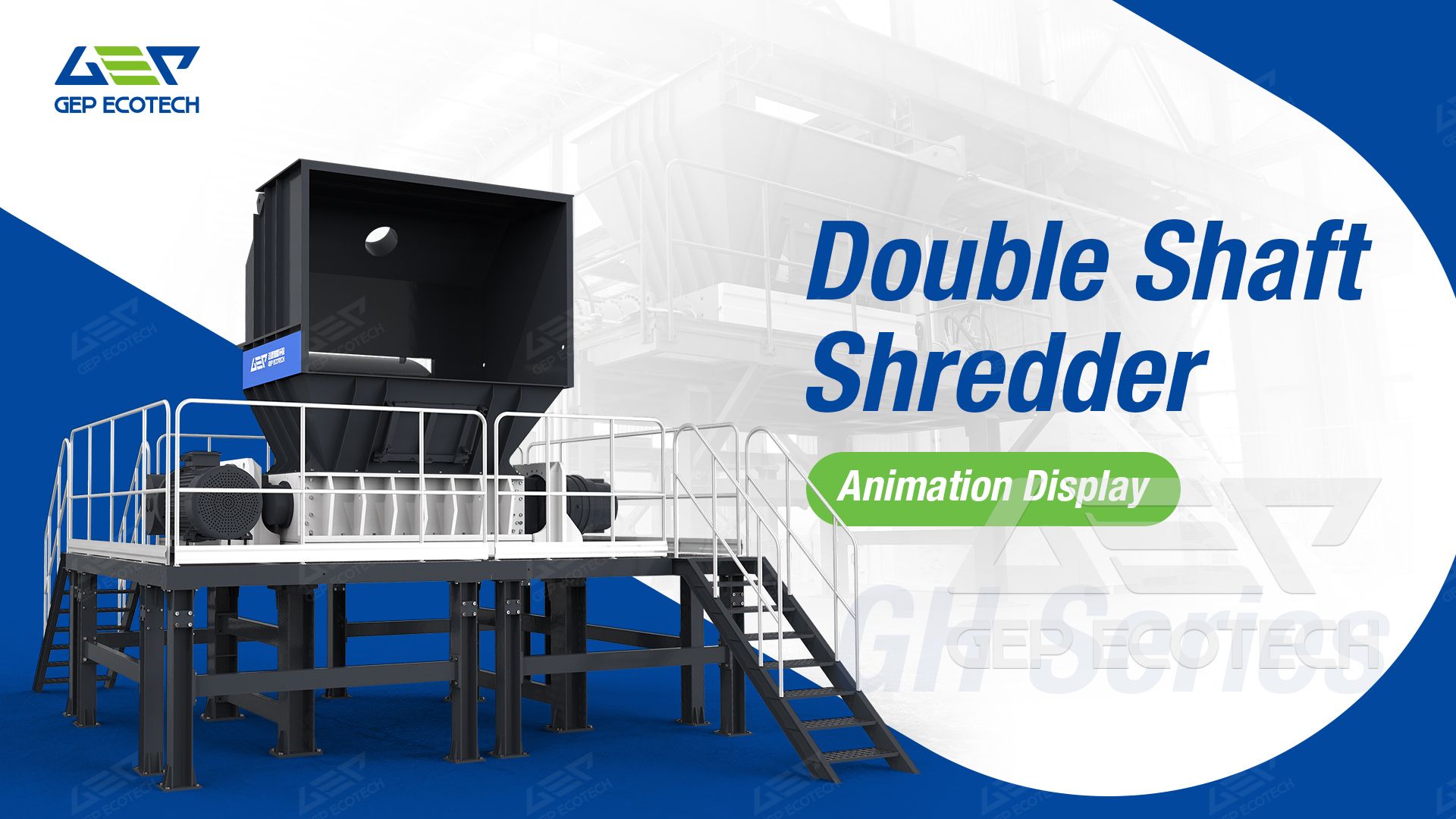

The two-shaft aluminum shredder is engineered for efficiency and durability. Its dual-shaft design enables it to effectively break down large pieces of aluminum into smaller, manageable sizes. This is particularly important for recycling plants that need to process various forms and sizes of aluminum scrap, including sheets, foils, frames, and cans.

Two-Shaft Aluminum Shredder for Aluminum Tube, Castings, Frames

Key Features and Advantages:

- Robust Construction: Built to withstand the rigors of shredding metal, these shredders feature hard-wearing materials and components.

- High Efficiency: The two-shaft mechanism ensures a high throughput rate, making the shredding process more efficient and cost-effective.

- Customizable Output: Adjustable settings allow operators to control the size of the shredded material, which is crucial for subsequent processing stages.

- Low Maintenance: Designed for ease of maintenance, these shredders reduce downtime and operational costs.

The two-shaft aluminum shredder is a testament to the innovation driving the recycling industry forward. By enhancing the efficiency and effectiveness of aluminum recycling processes, it not only benefits the environment but also contributes to a more sustainable and circular economy. As demand for aluminum continues to grow, the role of such specialized equipment in recycling will become increasingly important.