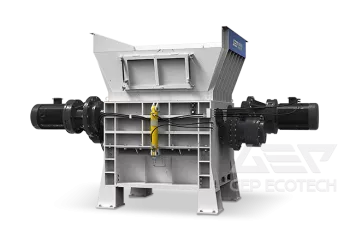

A leading auto dismantler in Southern Taiwan, processing 3,000-4,000 cars monthly, selected GEP ECOTECH's complete ASR processing plant to address their growing waste challenges. The integrated system effectively transforms automotive shredder residue into high-quality solid recovered fuel (SRF) through multi-stage shredding and advanced separation equipment. The solution achieves precise 30mm output specification (through a four-shaft shredder) critical for optimal SRF Shredding, with reliable 8t/h processing capacity supported by magnetic separator and eddy current separator for efficient metal recovery. This comprehensive Alternative Fuel Production system has successfully resolved the client's long-standing waste accumulation issues while creating sustainable value through quality fuel production. The customer reported complete satisfaction with both equipment performance and output quality, confirming GEP ECOTECH's expertise in delivering effective resource recovery solutions.

Home

{{headline}}

Back

{{headline}}