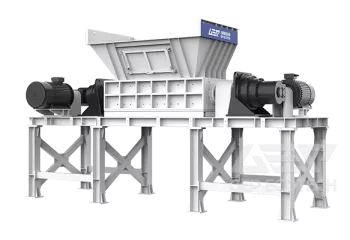

This project for an environmental protection company in Henan is designed to process textile waste and industrial solid waste into high-quality alternative fuel for cement kilns. The upgraded production line, with a stable capacity of 6-8 tons per hour, includes key equipment such as a Double-Shaft Shredder, Wind Sifter, Single Shaft Shredder, and a choice between an RDF Pellet Mill or a Waste Baler for final densification. The system improves waste sorting efficiency and fuel uniformity. Currently operating smoothly and exceeding performance expectations, it supports both economic and environmental benefits. The customer expressed great satisfaction with the equipment and professional service provided.

Home

{{headline}}

Back

{{headline}}