Introduction: With resource recycling as its mission, GEP ECOTECH has made great achievements in eight major areas: bulky waste, biomass, industrial waste, construction and decoration waste, waste tires, hazardous waste, food waste and domestic waste. Starting from this week, we will launch a series of articles entitled "Solid Waste Treatment System Tour" to let you know in one article how different types of solid waste are treated in a resourceful manner. Today we are launching the first issue: Bulky waste recycling system.

System Description

With the acceleration of new urbanization and the improvement of people's living standards, the elimination rate of large items such as sofas, mattresses, televisions, refrigerators and washing machines has accelerated, which has brought about many problems such as mountains of bulky waste, large sizes that are not easy to dismantle and difficult to transport, and low efficiency and insecurity of manual dismantling. In order to meet the market needs and solve the problem of bulky waste disposal difficulties, GEP ECOTECH has launched a bulky waste resource system that combines mechanical, electrical, hydraulic and intelligent technologies.

The system is designed according to the different recovery values of bulky waste. Through high-quality processing equipment and intelligent management systems, the valuable materials in bulky waste can be resourcefully utilized: bamboo and wood types can be separated out and made into wood-plastic and fibre boards; iron and springs can be melted back into furnaces; sponges can be made into recycled cotton, shoe soles and various decorative items; plastics, foam, rags and leather can be made into high calorific value RDF or SRF. If fine separation is not desired, the combustible components can also be sorted out and made into fuel for waste-to-energy plants.

The system usually consists of a bulky waste shredding system, feeding and discharging conveying system, magnetic separation and iron removal system, pulse dust removal system and intelligent control system, or the configuration can be flexibly adjusted according to the end use after treatment, ultimately achieving the purpose of improving the efficiency of terminal treatment and transfer, saving labour and time costs for enterprises, turning bulky waste into pieces and turning waste into treasure.

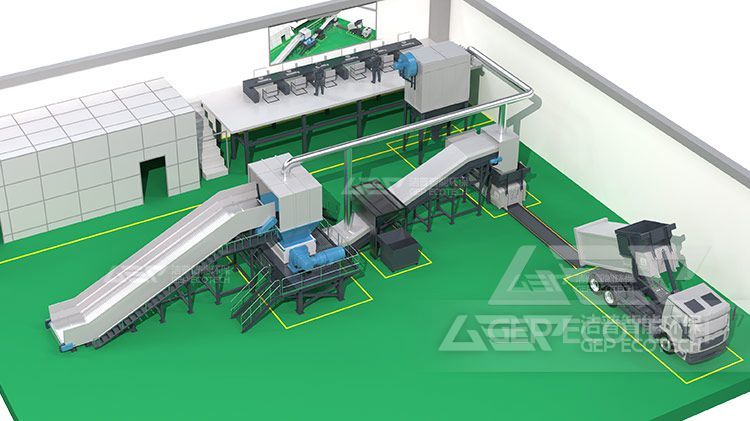

System Option A: Rapid Capacity Reduction

This solution is already being used in many cities in China. It uses a relatively simple "shredding + magnetic separation" process, which allows for rapid capacity reduction of bulky waste and reduces storage and transportation costs, making it ideal for use in small and medium-sized waste treatment centres and transfer stations. The compact layout of this solution offers a small footprint, high capacity and high efficiency, good containment and environmental protection. The core equipment is our invention patent product double shaft bulky waste shredder (patent number: ZL202011009400.0), imported alloy steel material made of cutters can achieve rapid shredding and substantial capacity reduction of various types of bulky waste, in addition to the machine also has stable performance, easy maintenance, long service life and other characteristics.

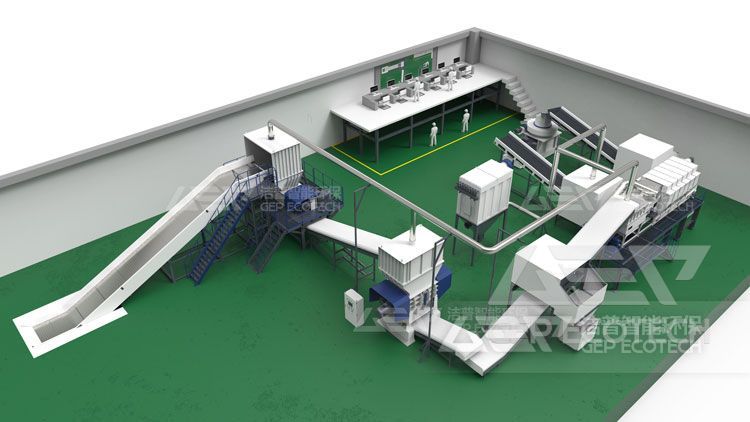

System Option B: Resourcefulness

The solution is specially designed for the bulky waste resource treatment centre, using the "two-stage shredding + two-stage sorting + compression molding" process, i.e. the bulky waste is successively shredded by the first stage of the double-shaft shredder and the third generation of the European version of the fine shredder, the shredded mixture is then passed through the magnetic separator to remove ferrous metals, the wind separator to select combustible light materials, and finally processed by the RDF molding machine into alternative fuels for transport to power plants and cement plants for incineration. Thus realizing the resource and energy transformation of the waste.

Both system solutions are equipped with automatic control systems and pulse dust removal systems for highly automated cleaning operations, as well as a powerful GI intelligence system that can summarize and analyze operational data at any time to assist in digital management.

System applications

GEP ECOTECH's bulky waste recycling system has been successfully operated in many waste treatment centres in many provinces and cities across China, and we have received recognition and praise as well as many valuable suggestions. In the future, we will draw wisdom from the suggestions and continue to optimize our equipment and solutions to better meet the market demand and create a solid waste resource treatment system with GEP's characteristics.