Unconsciously, the year 2023 is already half over. In the "mid-year report card" of GEP, there are new orders signed, "GEP-made" that are working day and night in anticipation of arriving at the project site as soon as possible, and there is no lack of some solid waste resources projects that have been completed and put into production. This article will take you to review several key projects.

Production Section

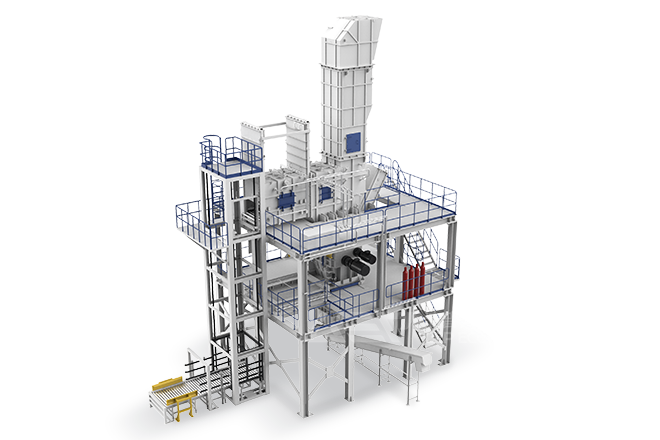

Hazardous Waste Shredding Project in North America

Given that the materials disposed of in this project are IBC drums, bottles with residual flammable liquids, oily fabric gloves and other hazardous wastes, our company has designed an intelligent Tower-type hazardous waste shredding system, which includes sub-systems such as lifting feeding system, crushing system, nitrogen protection system, carbon dioxide fire-extinguishing system, hydraulic auxiliary system, and intelligent control system, which can not only ensure the safety of the material disposal process, but also meet the process requirements of the project.

Shipment Section

European Construction Waste Recycling Project

The production line equipment of this project includes crushing equipment, conveying equipment, sorting equipment, screening equipment, dust reduction equipment and intelligent integrated control system, which is responsible for separating metal, wood, plastic and other debris in the construction waste, crushing concrete and bricks into the required particle size, and recycling them to be used as construction aggregate. It would be more perfect if our automatic brick making production line is configured at the terminal.

Installation Section

Scrap Metal Treatment and Recycling Project in North America

The project is a leading aluminium production and processing company in North America invested in scrap metal processing and recycling projects, a collection of our shredding"elite" (pre-shredder, medium shredding of double shaft shredder, fine shredder of the European version of the single-shaft fine shredder) and sorting "expert" (magnetic separator, eddy current sorter and trommel screen), and strive to make the fine treatment of the scrap metal after the new opportunity.

Completion Section

Zhejiang Sanitation Resource Recovery and Disposal Centre EPC Project

The project is a resource recovery and disposal EPC project integrating a domestic waste sorting and shredding system, a pre-processing system for bulky waste and garden waste, a recyclables sorting system, and an RDF forming system. The equipment includes dozens of double-shaft shredders, single-shaft fine shredders, trommel screens, wind separators, magnetic separators, RDF moulding machines, hydraulic balers, conveyors, dust removal systems, etc., which will ultimately achieve the effective use of combustible rubbish for energising and resourcing of recyclables.

Jiangxi Bulky/Garden Waste Resourcing Project

The project adopts the process route of multi-stage shredding+multi-stage sorting extrusion moulding, with more than ten sets of equipment’s including bulky waste shredder, light material shredder, magnetic separator, wind separator, RDF moulding machine, chain conveyor, belt conveyor, etc., and the final products, such as leather, fabric and other light materials, are made into RDF fuel, metal is selected by the magnetic separator to be recycled, and wood is piled up separately for disposal, so as to achieve the best use of useful materials.

Shanxi Village and Township Domestic Waste Comprehensive Treatment Project

The project is located in the first batch of rural domestic waste classification and resource utilisation demonstration counties in China, and our company won the bidding with the special shredding equipment for domestic waste, screening equipment, conveying equipment, sorting equipment and compression equipment. The programme has simple process, flexible configuration, low capital investment and low operating cost, which not only reduces the burden of waste, but also increases the income, and can be promoted in villages and towns all over the country.

Zhejiang Domestic Solid Waste Resourceful Disposal Project

The materials disposed of in this project are general domestic miscellaneous waste, mainly combustible materials such as plastic bags, greaseproof paper, used clothes, etc. Through the fully automated shredding and sorting and RDF moulding process configured by our company, the combustible materials will be transformed into high-density and high calorific value RDF fuel. On the basis of not polluting the environment and making full use of the residual value of waste, the high value of waste is successfully realised.

The first half of the year, when big projects were signed, started, completed and put into production one after another, will surely be the best start for the second half of 2023!