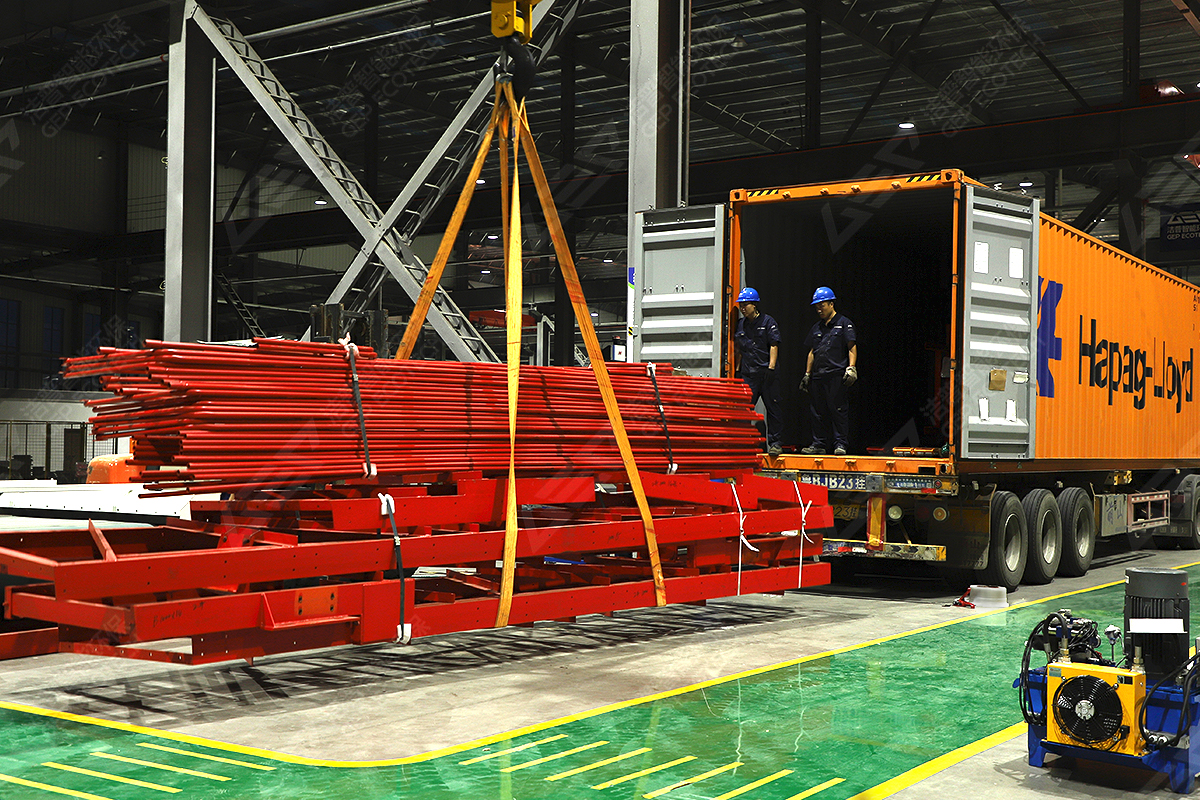

On June 26, the first batch of GEP tire disposal production line was successfully loaded in the workshop and will be sent to Southeast Asia. The two waste tire disposal production lines are delivered in two batches, the second batch is expected to be shipped in early July.

This tire crushing and disposing production line is designed and customized according to customer’s needs, and its quality has reached the international advanced level. In the production process, all departments strictly fulfill the assignment of responsibility, promote the tasks with quality and quantity and complete the production and delivery on time.

Tire pyrolysis oil refining is an environmental protection development mode which integrates environmental protection and resource reuse. Before pyrolysis treatment of waste tire, crushing and steel wire separation are needed to achieve the purpose of crushing, volume reduction and transportation cost reduction. Customer purchases GEP waste tire disposal production line mainly uesd for crushing pretreatment of tire pyrolysis oil refining and power generation. In the early stage of project cooperation, customer fully affirmed GEP’s solution through visit workshop, inspection and comparisons. Finally they chose to cooperate with GEP.

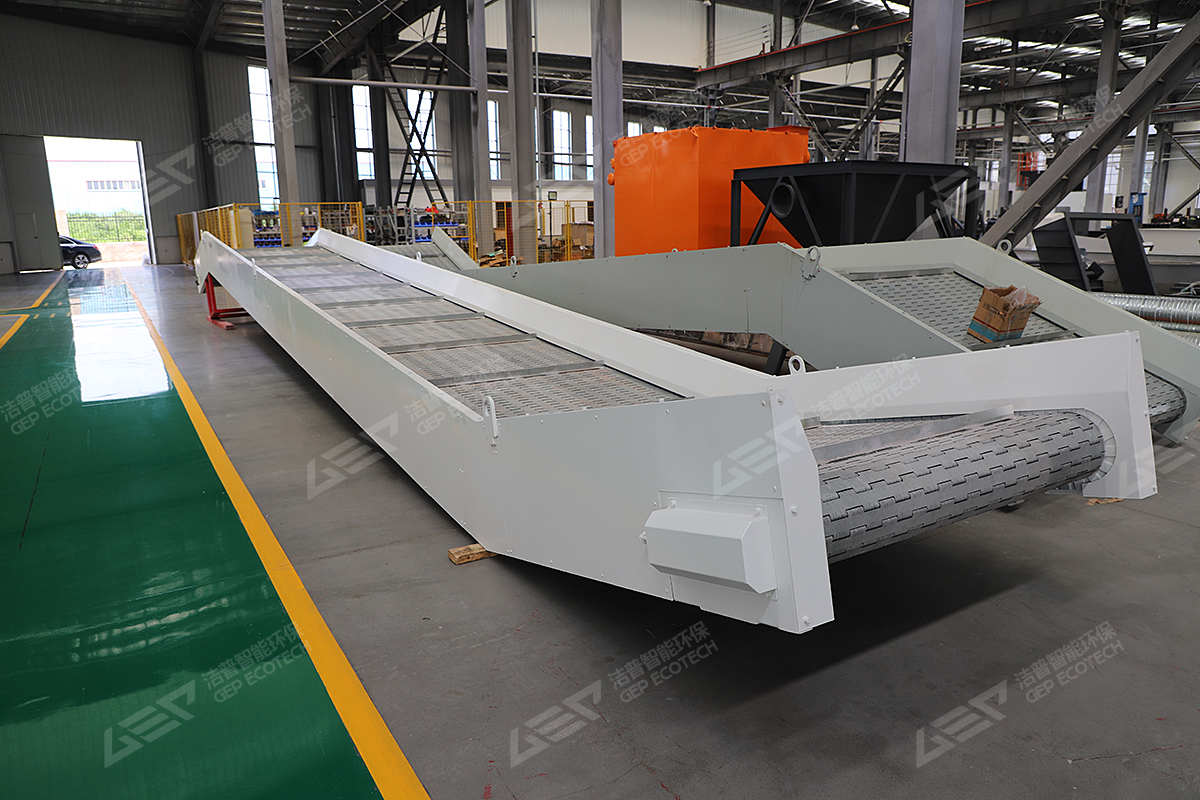

GEP waste tire disposal production line is composed of tire wire puller, chain plate conveyor, double-shaft shearing shredder, roller screen, belt conveyor and intelligent detection system. The production line adopts intelligent, customized and systematic design. It has the characteristics of small area, less investment, low energy consumption, environmental protection and pollution-free, high automation of the whole set of equipment and simple operation. The series of products have passed the CE certification of European Union, and the products are made with high standards. It is the escort for deep resource utilization such as tire cracking, oil refining, co-incineration, grinding and so on.

Characteristics of waste tire disposal production line

Modular design, little space taking

The production line follows the principle of reasonable and intensive land use. It adopts the structural design combining the double-shaft shearing shredder and the annular roller screen. The reasonable, which not only guarantees the output and the size of the discharged material to meet the requirements, but also meets the needs of the planning and construction of the customer's tire disposal production and operation.

GI intelligent monitoring and operation automation

The entire production line adopts centralized control of the intelligent intelligent control system to improve the safety of production control; real-time monitoring of the status, timely grasping the operation status of the equipment, forming an effective early warning mechanism, effectively reducing the equipment failure rate and maintenance time, and reducing maintenance and operation costs. Greatly improve the operating efficiency of the production line.

High wear-resistant cutter, strong crushing capacity

The raw materials are imported from Europe, the wear resistance is high, the hardness is high, it can be repaired and used repeatedly, and the crushing ability is strong. After hot processing with advanced heat treatment technology, the cutting tools are machined by high precision machine tools with long service life and effectively improve the production efficiency.

As the pioneer of solid waste resource utilization,GEP adheres to the quality to build a brand, serves to improve its value, pay attention to technical innovation, and continues to move to a higher level in product quality, strives to make GEP into a well-known brand in solid waste disposal professional manufacturer and comprehensive service provider, contributing to build a resource-saving and environment-friendly society. At present, GEP has passed the ISO9001 international quality and environmental protection system certification, the quality won more customers’ approve, the product exports to many countries and regions such as North America, Europe, Southeast Asia and so on.

In the future, GEP will continue to play its own technical advantages, push forward the equipment function upgrade, intelligent upgrade, improve the comprehensive competitiveness, grasp the development opportunity, and actively explore the market share of the cleaner and intelligent environment protection in the field of solid waste disposal.