The large-scale development of wind power in our country began in 2004, although it started late, it developed particularly rapidly. At present, our country is the world's largest fan manufacturing country. According to data from China Power Network, by the end of 2022, China's cumulative installed capacity of offshore wind power has reached 32.5 million kW, continuing to maintain the world's largest installed capacity of offshore wind power. According to experts' prediction, in 2023, the cost of wind power generation in our country will plummet, the cost of wind power will usher in the first low in history, and the scale of wind power installation will usher in the first peak in history.

However, although wind power is better in the early stage of development, the treatment of the waste bldashas also become a big problem.. According to incomplete statistics, by 2022, China will have 595 wind turbines maturing, and by 2030, the number will climb to 12,904. After the decommissioning of the fan, 85%-90% of the total amount of fan can be used, but most of the blades are reinforced by glass fiber reinforced thermosetting resin base. The cutting process of this kind of material recycling is very complex, and the cutting processing of the blade front has become a problem in the industry.

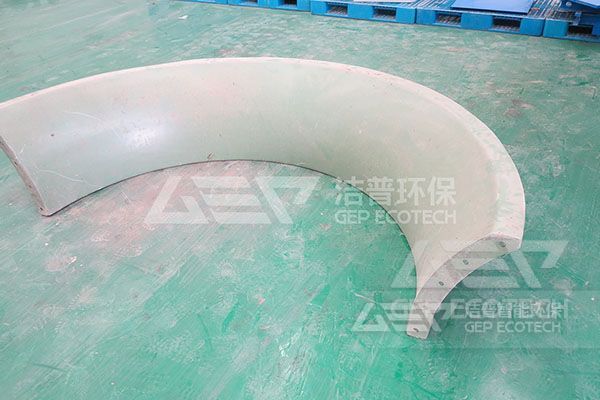

As an expert in the field of industrial solid waste disposal, GEP ECOTECH is also constantly exploring on this issue. Through exchanges with domestic well-known wind power enterprises and repeated experiments, it finally introduces equipment specifically for wind power blade crushing and decomposition, which can break the blade to the long strip material within 100mm, so as to facilitate the processing of the back end process. Greatly save manpower and material costs, if you are interested, you can contact by phone or wechat, looking forward to your communication and cooperation.