The tire recycling industry has attracted the attention of many investors. For some small and medium-sized enterprise investors, the sale of waste tires into rubber powder can be said to be profitable. The recycling of waste resources can not only obtain local support, but also generate profits. Therefore, the prospects for the recycling of waste resources are broad. Today we will use an article to talk about how waste tires are processed by shredder to form rubber powder.

The process of making rubber powder from waste tires probably has the following three stages.

The tire is crushed into pieces

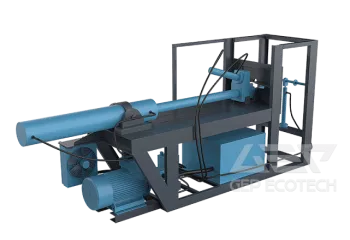

The so-called tyre breaking into pieces is easy to understand, because the whole tire cannot be directly formed into tire powder, and the tire breaking into pieces requires a tire shearing shredder to complete. Relying on the drive provided by the motor and the reducer, the cutters on the two main shafts are driven to cut in opposite directions, and the entire waste tire is gradually cut into smaller pieces, which is convenient for entering the next process.

Separation of impurities in tires

What is the separation of impurities in tires? We must know that the composition of our tires is not only rubber, but also fiber and steel wire. Tire powder is a kind of pure rubber powder. Therefore, the steel wire and fiber of tire should be gradually separated when forming rubber powder. In this peeling process, the tire is gradually broken into very small rubber particles. Wire separators, tire fiber separators, and self-unloading iron removal systems will be used in this process.

Tire powder

Finished removing impurities from the tires and crushing the fine particles of the tire homogenization. This part of the material can be transported into the tire milling equipment through the conveying equipment. The tire mills of different meshes can be selected according to the mesh size of the tire rubber powder we selected. The common meshes are 20 meshes, ranging from 80 meshes to 100 meshes.

Through the three stages of tire disposal, you can understand how tires form rubber powder. If you are currently considering investing in this industry, you can contact our company and we will issue you relevant plans to facilitate your project investment Budget.