How is iron processed after recycling? People generally think that the recycling is done directly after processing, but in fact the process of reusing the iron after recycling is not so simple. This requires the use of our double-shaft shredder.

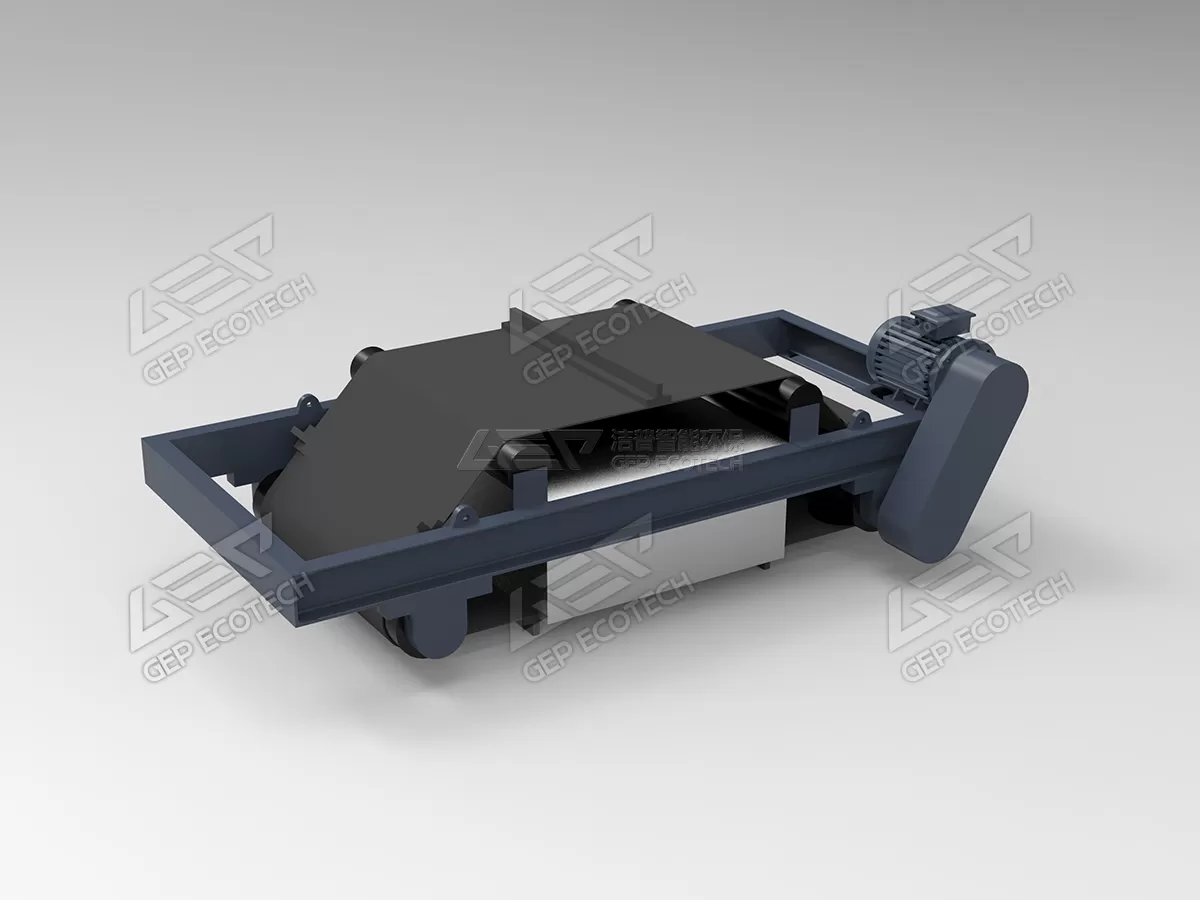

Magnetic separation of iron recycling

For solid waste after recycling, like metal cans of different materials, the method generally used is magnetic separation. Magnetic separation is a treatment method that uses the magnetic differences of various substances in solid waste to sort them in an inhomogeneous magnetic sound. After the solid waste is fed into the magnetic separator, the magnetic particles are magnetised under the action of the uneven magnetic sound, thus being subjected to the action of magnetic attraction, so that the magnetic particles are sucked into the cylinder and discharged with the cylinder into the discharge end; the non-magnetic particles remain in the waste due to the small magnetic force they are subjected to. The magnetic field source used for magnetic separation is generally either an electromagnet or a permanent magnet.

The use of double-shaft shredder to reduce capacity and volume

The double-shaft shredder uses two sets of opposing rotating cutters to shear the iron. Our equipment has the advantages of high torque, low speed and stable operation, and is able to shear the material into a suitable size for further recycling. Because many steel mills have strict feed requirements, the material needs to be shredded to a small size before it can be put into the smelter to make the most of it.

How much does a double-shaft shredder cost

Our machines are all customisable, which requires specific information from the customer about the material so that we can recommend the most suitable machine model. Because of the different requirements of our customers and the complexity of the material, we ask our customers carefully about the material and its disposal requirements in advance. So please don't take our questions as a problem. Only when we understand the real needs of our customers can we recommend the most suitable equipment to help solve the problem and reduce the investment costs of our customers.