Biomass Crushing is the process of reducing larger pieces of biomass, such as woodchips, bark, straw, or other plant-based materials, into smaller, more manageable pieces or particles. This is achieved by using a biomass crusher, which can be a machine that utilizes sharp cutting blades or hammers to break down the biomass material.

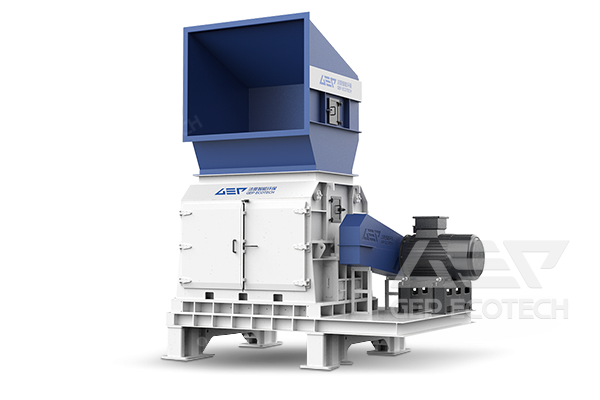

Efficient shredding, precise discharge, and holding of complex materials!GXB biomass sherdder, specially designed for the resource utilization and disposal of various types of biomassEasily handle material handling capacities ranging from 3.5 to 16 tons/…

The GXB biomass fine shredder is specially designed for the fine shredding stage in biomass recycling lines. It features a large-diameter rotor to increase linear velocity and rotational inertia and a large, adjustable screen area ensures effective…

Circulating fluidized bed (CFB) boiler power plants have high requirements for fuel pretreatment, necessitating a series of crushing and screening processes for biomass such as straw. The size of biomass fuel entering the furnace is generally required to…

The energy consumption of a biomass crusher depends on a number of factors, including the type of equipment, specifications, workloads, material types and treatment methods. In general, the energy consumption of biomass crusher varies due to several…

The energy issue is a global issue, and biomass power generation, which does not rely on exhaustible fossil fuels such as oil and coal, is receiving increasing attention and is being popularized due to its friendliness to the Earth's environment.Biomass…

A biomass pellet fuel production line is a type of biomass energy utilization technology that uses organic biomass materials such as wood, sawdust, straw, rice straw, and soybean stalks to produce various shaped fuels through physical processing such as…

If the raw material composition is mainly corn dry yellow straw and rice straw, etc. The technical requirements for biomass crushing of biogas fermentation: continuous working processing output: ≥10t/h (crushing output); after processing, 90% of the…

GEP participated in four cogeneration projects of this large group, with a total of seven large-yield biomass straw shredders. This series of biomass shredders have large-capacity working area design, unique anti-winding fixed knife design, high-quality…