When a mountain of car interiors piled up in a car dismantling plant in Taiwan is no longer a "hot problem", but has become a popular high-value fuel for sale—this scene was achieved through GEP ECOTECH's first SRF alternative fuel project for car interior preparation in Taiwan. As the largest car dismantling enterprise in southern Taiwan, this customer has to dismantle 3000-4000 cars per month. The disposal of massive interior materials used to be a major obstacle to production. Now, GEP ECOTECH's customized solution not only solves the pain point of solid waste disposal, but also injects new momentum into Taiwan's alternative fuel industry.

Breaking Down the "Urgent Need" of Giants: Why SRF Is the Optimal Solution?

In Taiwan's automotive dismantling industry, "environmental compliance" and "resource recycling" have long been core propositions. With the growth of car ownership, the interior materials (such as foam, leather, plastic) generated from dismantling have long been a problem for enterprises due to their complex composition and high disposal costs—they occupy space for stacking, burn and pollute the environment, and landfill does not meet environmental protection requirements. The emergence of SRF (Solid Recycled Fuel) has precisely opened up a two-way channel between "solid waste disposal" and "energy substitution": it can convert difficult to degrade interior materials into high calorific value fuels, replacing traditional fossil fuels such as coal and natural gas, and applied in scenarios such as cement kilns and power plants. It not only reduces the amount of solid waste landfilling, but also alleviates energy shortages, perfectly meeting the industrial needs of Taiwan's "low-carbon transformation".

For dismantling giants, the implementation of the GEP ECOTECH project not only solves the production pain point of "fast material accumulation and difficult handling", but also shifts from "passive disposal" to "active revenue", becoming a benchmark case for Taiwan dismantling enterprises to transform into "resource upgrading".

Core Weapon: Four-Shaft Shredder, the "Efficiency Responsibility" That Supports Production Capacity

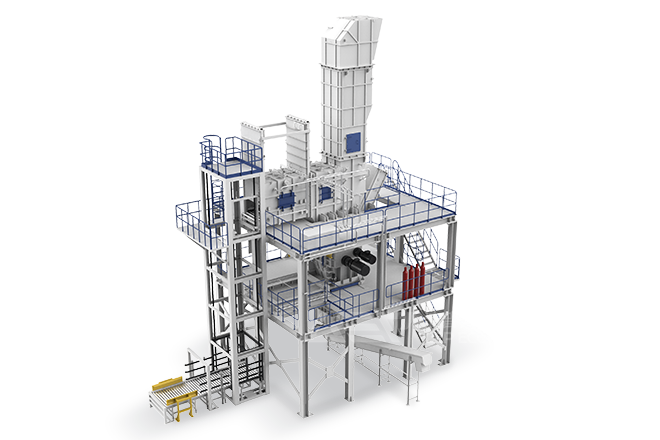

A stable and efficient SRF preparation system cannot do without the "hard core strength" of the core equipment. In the customized solution provided by GEP ECOTECH for this project, the four-shaft shredder can be regarded as the "efficiency engine", directly determining the processing capacity and discharge quality of the entire process.

Compared with traditional shredding equipment, this four-shaft shredder has outstanding advantages: firstly, it adopts a four blade roller design with built-in material grasping function, without the need for additional pressing process—this not only simplifies the process flow, but also doubles the tearing and shearing force, even tough leather and high-density plastic can be easily shredded; Secondly, the equipment is equipped with precise screening screens, which can stably control the discharge size within 30mm. This size not only meets the feeding requirements of the subsequent sorting process, but also lays the foundation for the stable calorific value of SRF; Finally, the stability of the four shaft structure is strong. After the entire system is put into use, it always maintains a high design capacity and operates without faults, reducing the burden on the subsequent sorting process—the more thorough the pretreatment, the higher the metal purity of the subsequent magnetic separation and eddy current separation, the less impurities in the SRF fuel, and the more recognized the quality by buyers.

It can be said that it is the "efficiency, stability, and precision" of the four-shaft shredder that supports the production capacity and quality of the entire project, becoming the key to achieving a win-win situation of "environmental protection+revenue" for the customer.

Customer Voice: Far Beyond Expectations, Trustworthy "Win-Win Partner"

"The project we collaborated on with GEP ECOTECH far exceeded our expectations!" the customer manager commented, "From material shredding to sorting completion, the connection between each link is particularly smooth, and the purity of the sorted metal is high. When SRF fuel is sold, buyers also recognize the quality, completely solving our material disposal problem." Moreover, the GEP ECOTECH team provides excellent service, with timely delivery and installation. During training, the operation and maintenance details are explained clearly, and new workers can quickly get started, fully meeting our production needs for stable and efficient operation.

The phrase "far beyond expectations" not only recognizes GEP ECOTECH equipment and technology, but also affirms the "GEP ECOTECH style service"—from customized solutions and equipment installation, to subsequent training and maintenance, GEP ECOTECH has always served as a "long-term partner", providing customers with full lifecycle support. This is also the key to GEP ECOTECH's ability to achieve "first case, benchmark" in Taiwan market.

From Taiwan's first automotive interior SRF project to providing a win-win solution of "environmental protection+benefits" for dismantling enterprises, GEP ECOTECH not only demonstrates its technological strength in the field of solid waste resource utilization, but also promotes the development of Taiwan's alternative fuel industry with practical actions. In the future, GEP ECOTECH will continue to specialize in specific fields and provide customized solid waste treatment solutions to global customers, making the green cycle of "turning waste into treasure" the norm for industrial upgrading.