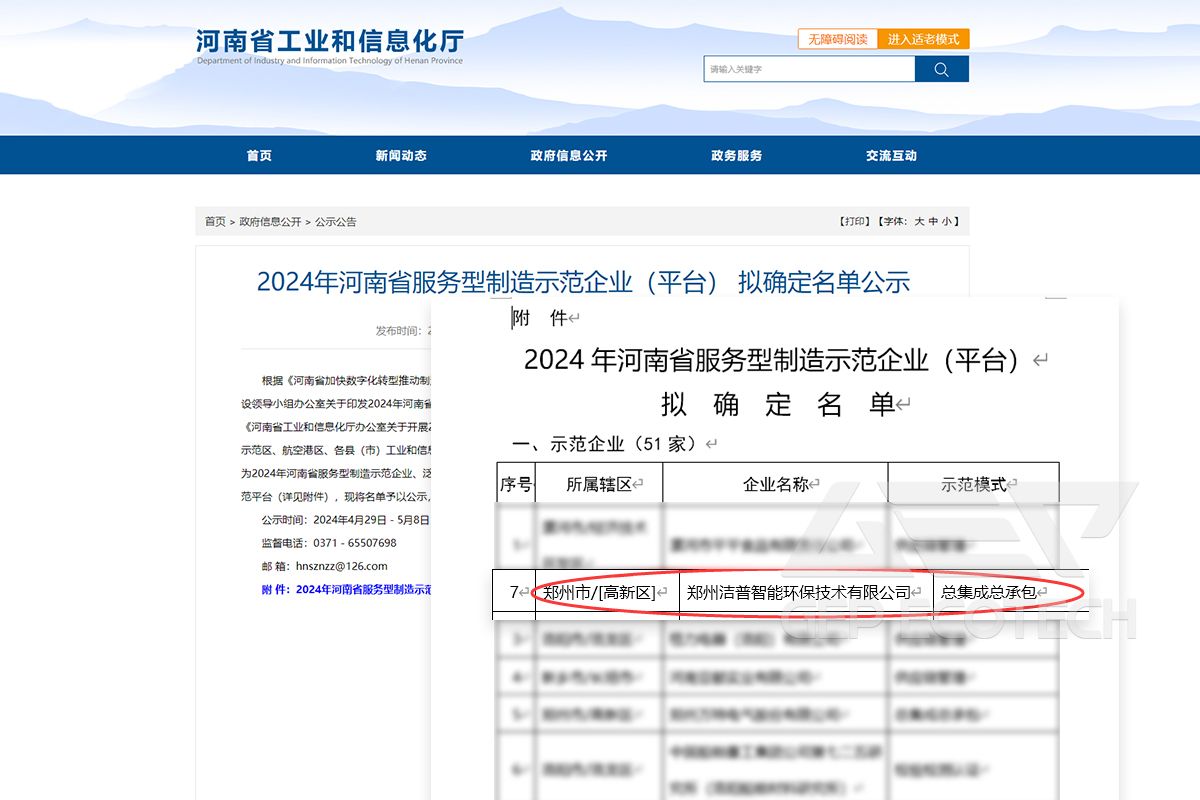

According to the spirit of documents such as the “Action Plan for Accelerating Digital Transformation and Promoting High-End, Intelligent, and Green Development of Manufacturing Industry in Henan Province (2023-2025)” (Yuzheng [2023] No. 32), after strict screening and expert evaluation, 51 enterprises including GEP ECOTECH, Gree Electric Appliances, China Shipbuilding Heavy Industry, Sanquan Food, and Synear Food jointly won the title of “2024 Henan Province Service-Oriented Manufacturing Demonstration Enterprise”.

Service-oriented manufacturing, as a new manufacturing model and industrial form that integrates manufacturing and services, is becoming an important direction for promoting the deep integration of advanced manufacturing and modern service industries. This selection is not only a recognition of the company’s years of exploration and efforts in the field of environmental protection equipment, but also a recognition of the company’s significant achievements in such aspects as R&D, manufacturing, and service.

Innovative R&D Capabilities

The company adheres to the concept of independent innovation, actively deepens industry-university-research (IUR) and application cooperation with well-known universities and research institutions, introduces cutting-edge global technology, and builds inter-disciplinary R&D platforms. Through close collaboration with partners, fully leveraging their respective professional advantages, combining production needs with scientific research capabilities, leading technological breakthroughs through theoretical innovation, and promoting product function optimization and industrial upgrading. At the same time, the company has advanced digital management systems that can flexibly customize solutions to meet the diverse needs of the market.

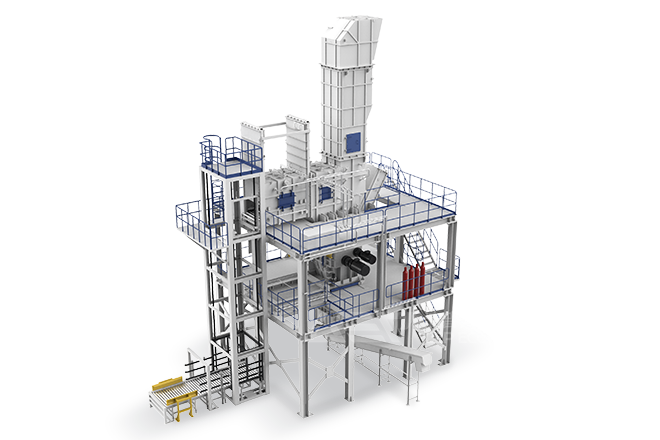

Manufacturing Capability

In the modern intelligent manufacturing base covering an area of 66,000 m2, advanced CNC machining equipment is integrated, such as high-precision CNC vertical machining centers, large-scale CNC gantry machining centers, CNC lathes, CNC wire cutting, forming a strong high-precision and cutting-edge manufacturing cluster. The company not only efficiently produces and delivers hundreds of sets of intelligent environmental protection equipment on time every year, but also quickly responds to market demand, providing comprehensive solutions for the disposal of such solid waste as industrial waste, municipal solid waste (MSW), construction waste, agricultural and forestry waste.

Service Support Capability

The company promotes new industrialization with high standards, continuously improves pre-sales, in sales, and after-sales service systems, and has formed diversified models such as “manufacturing+service” and “product+system solutions”. The company provides users with a full lifecycle service from R&D design, production and manufacturing, installation and commissioning, delivery for use, to operation and maintenance support, ensuring that users receive a high-quality service experience. Meanwhile, the company continues to strengthen the talent development of its service team, forming a team that is creative, cohesive, executable, and capable of fighting tough battles, providing users with more professional and efficient services.

General Integration and Contracting Capability

The company relies on a mature and complete R&D, manufacturing, and service system, continuously integrating various resources, and providing general integration and contracting services in the field of energy conservation and environmental protection, covering on-site surveying, scheme design, civil construction, manufacturing and procurement, installation and commissioning, production training, and after-sales support. This service model not only simplifies project management processes and improves project execution efficiency, but also ensures that every link of the project can meet high standards of quality requirements by optimizing resource allocation and precise services from professional technical teams. It is precisely these advantages that have enabled the company’s general integration and contracting services to receive unanimous praise from owners in different solid waste disposal projects both domestically and internationally.

As a service-oriented manufacturing demonstration enterprise, the company will continue to deepen its efforts on the path of “R&D+manufacturing+product+service”, continuously improve the added value and market share of its products, and provide continuous energy for the improvement of quality, efficiency, and transformation and upgrading of the environmental protection equipment manufacturing industry.