On April 23, the fuel crushing and disposal production line of the Jiepu NNBP 25MW biomass power station project was successfully completed. The equipment will be shipped from the port to Southeast Asia, which will lay a solid foundation for the company to further expand its overseas market.

In the factory, three trucks loaded with Jiepu large solid waste crushing equipment have been loaded. The trucks carrying the equipment will be rushed to the port without a stop, shipped out to Southeast Asia by sea, and delivered to customers on time.

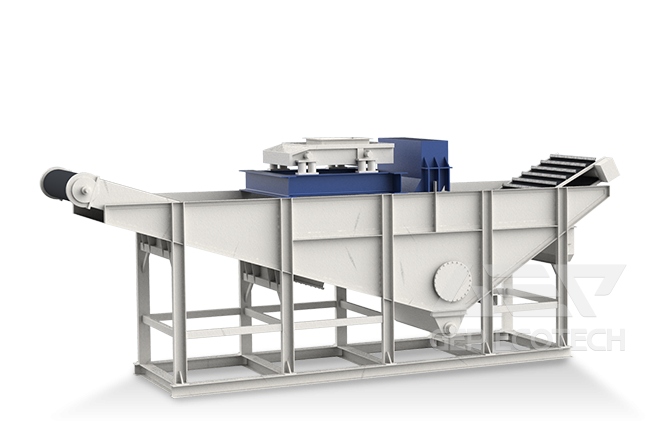

It is reported that the NNBP 25MW biomass power station project is a strong joint venture between Jiepu Intelligent Environmental Protection and Fortune 500 companies in the field of biomass power generation. This cooperation has effectively expanded the market share and brand awareness of Jiepu products. This shipment is the biomass fuel crushing and disposal production line of the Jiepu NNBP 25MW biomass power station project. The production line is mainly composed of three twin-shaft shear crushers and a plurality of chain conveyors. It can crush 40 tons of materials per hour and is broken into pieces of less than 100mm, making it easy to store and transport. And large-scale supply.

In order to ensure the efficient operation of the production, delivery on time, to do enough preparations. After signing a contract with European customers in October last year, Jiepu Intelligent Environmental Protection has formulated a complete equipment manufacturing plan to track the production progress of each process and coordinate production. All departments work closely together with high standards and strict requirements. According to the established time nodes and delivery sequence, the production is reasonably organized to ensure the timeliness of equipment delivery.

The NNBP 25MW Biomass Power Plant project team is part of a well-known international group. The group is a multinational Fortune 500 company with world-leading engineering design and consulting capabilities in the energy sector, involving pulp and paper, chemicals, bio-refining and many other business areas. Based on the characteristics of biomass fuel, Jiepu Intelligent Environmental Protection has independently designed and developed the biomass fuel crushing and disposal production line. The overall structure is professionally designed according to customer needs, in line with the actual production needs of customers. In addition, the Jiepu Biomass Crushing System uses a chain-plate intelligent feed that automatically adjusts the feed rate based on the main motor load. The machine has high feed efficiency and high crushing efficiency, which makes the feed smoother, avoids idling, and greatly increases the output. It is the ideal equipment for biomass power plants.

Process flow of biomass fuel crushing and disposal production line:

Biomass raw materials such as sugar cane skin, bark, and branches are transported from the raw material site to the workshop, and the biomass raw materials are stacked in the direction of the chain conveyor feeding to prepare the materials, and the raw materials enter the biaxial shear crusher. After that, it is pushed into the crusher by the upper presser for crushing treatment. When the crusher is running, the intelligent control system temporarily suspends the operation of the chain conveyor. Some raw materials are temporarily stored on the conveyor to ensure that the raw materials are continuously supplied in sufficient quantities, thereby avoiding equipment failure caused by the accumulation of biomass raw materials in the crusher compartment. The crushed biomass raw materials are collected and collected on one discharge conveyor, and the output biomass fuel is to be processed in the next step.

Based on the cutting edge of science and technology, Jiepu intelligently develops intelligent solid waste crushing equipment that meets the requirements of solid waste disposal industry. It introduces the concept of green environmental protection, high efficiency and energy saving in all aspects of design, and always implements the concept of sustainable development and is committed to providing customers with The comprehensive solution covers a full range of mechanical equipment products, and provides a series of applications, parts, services, after-sales and other solutions. After years of experience in domestic and international markets, the products have excellent benchmarking quality, economic benefits and environmental benefits. Up to now, Jiepu intelligent environmental protection customers have spread across many countries and regions, forming a certain brand awareness and influence.

Sailing started and struggling. Jiepu intelligent environmental protection responds to the national “One Belt, One Road” policy and actively takes the international route. More and more intelligent solid waste equipment has gone abroad, and has been favored and recognized by customers all over the world for the quality of Jiepu intelligent environmental protection equipment. In the future, Jiepu Intelligent Environmental Protection will continue to innovate products, improve product quality, improve after-sales service, and make high-quality intelligent solid waste crushing equipment to serve global users.