On July 26th, the large biomass fuel pre-shredding system was officially sent to Northeast Thermal Power Plant. This shipment means GEP products are again highly recognized by the biomass power generation market, and also marks the upgrade version of GEP biomass shredding equipment —— the second generation of double shaft shredder is officially landed!

With the strong encouragement and support for the development of renewable energy, biomass power generation investment enthusiasm continues to rise, all kinds of agricultural and forestry waste power generation projects have started. According to the data of the State Energy Administration, in 2019, the cumulative installed capacity of biomass power generation in China reached 22.54 million kilowatts, increased 26.6 percent over the same period last year; China's biomass power generation added 4.73 million kilowatts; China's biomass power generation 111.1 billion kilowatt-hours, increased 20.4 percent over the same period last year, continued to maintain a steady growth momentum.

The biomass cogeneration project belongs to the comprehensive utilization of waste resources. It can not only solve the problem of agricultural solid waste disposal, create additional income for farmers, but also solve the problem that burning straw seriously pollutes the environment and endangers people's health in autumn and winter. It plays an important role in improving urban and rural air quality and improving the living environment of urban and rural residents. However, at present, the biomass cogeneration project is faced with the problem of fuel crushing —— the single machine crushing output is low, the production dust is large, and the maintenance and repair are difficult.

To solve the problem of biomass crushing, biomass fuel pre-shredding system is coming

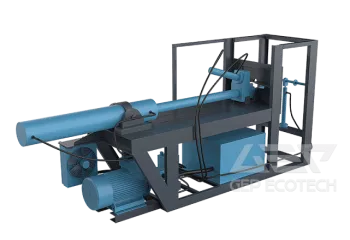

Considering the characteristics of biomass fuel, GEP Ecotech independently developed and designed biomass fuel pre-shredding system. The biomass straw feed device, core crushing equipment, finished product conveying device, intelligent control system and so on were comprehensively optimized and upgraded. The upgraded crushing system has good effect on corn, straw, soybean, peanut, cotton, reed, and branches produced by agricultural and forestry waste. GEP ECOTECH biomass fuel crushing system has the advantages of large capacity, intelligent maintenance, cooperative optimization and so on, and successfully solves the problem of fuel crushing pretreatment in the field of biomass thermo electricity.

This large scale biomass shredder delivery is GEP ECOTECH based on users’ needs, provide own high-end equipment and intelligent technology advantages, specially developed and designed for large-scale biomass shredding.

Innovative process design to create industry leading position

The Chain plate conveyor or grabbing machine evenly feeds the biomass agricultural and forestry wastes into the shredder. The shredder breaks the materials through the working principle of shearing, shreddingand extrusion. The shreddedmaterials are sorted out by the magnetic separation,then transported to the finished material area or transferred to the next disposal process by the belt conveyor. The whole production system can realize airtight transportation, negative pressure dust reduction and clean production.

The advantages of large scale biomass fuel pre-shredding system

Large capacity, high crushing efficiency —— high crushing efficiency, single machine capacity up to 30-60 t/h; unique anti-winding device design, solve the problem of bundle disposal, ensure the stability of equipment operation.

System linkage, intelligent feeding —— design of a complete set of uniform conveying device, can achieve intelligent adjustment of feeding.

Less dust, environmental protection —— core crushing equipment with low speed, large torque design, good stability, small dust pollution.It can be equipped with a complete set of intelligent dust control system for each dust point, high efficient dust control and less energy consumption.

Intelligent, GI monitoring ——GI intelligent patent technology, multi-point monitoring, intelligent maintenance, big data analysis, timely understanding the operation status of equipment, to achieve intelligent, digital and refined production line monitoring and management.

Excellent performance, wear-resistant cutter —— cutter use European imported material, better wear resistance, large shear force, long service life, good interchangeability, save labor maintenance costs.

After the equipment arrives at the project site,GEP after-sale service engineer will go to the equipment installation site at the first time, realize the equipment arrival and guide the installation time seamless docking, the service work zero waiting! Help customers greatly shorten the installation and commissioning time, help customer project acceptance and delivery in advance escort.

To win by technology, to win by quality, to focus on the field of solid waste recycling, GEP ECOTECH continues to accelerate, stride forward to the established goal, strictly control every link in the manufacture of equipment to create fine products, play the strongest sound of the solid waste disposal industry.