The double-shaft shredder is currently the most widely used new type of shredder in the shredding equipment market. What are the criteria for judging the quality of the equipment? What are the precautions for purchasing dual-shaft shredder equipment? This article introduces you:

1.Motor: The motor must be a reliable product. Never use refurbished motors or poor-quality motors, because the copper enameled wire diameter of these motors does not meet the requirements of the rated current of the rod machine. Therefore, the motor is easy to burn or the driving force is insufficient, which affects the rotation speed of the double-shaft shredder and the overall crushing effect.

2. Bearings: The quality of bearings directly affects the production efficiency of the twin-shaft shredder and the quality of particles.

3. Steel plate: The thickness of the steel plate must meet certain requirements.

4. Blades: Professional manufacturers have various specifications of blades suitable for different materials. Some blades called general multifunctional shredders will have differences in output and blade wear according to the different materials to be crushed. When choosing, the users need to verify the blade specifications, material, mouth shape.

5. Control system: For the double-shaft shredder, because there are many uncertain factors in the shredding process, in order to protect the motor and avoid damage to the blade, the double-shaft shredder control system needs to have the function of automatic control, reasonable reverse rotation , increasing productivity and reducing energy consumption.

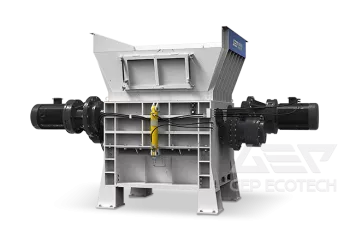

GEP ECOTECH intelligent dual-shaft shredder fully meets the market demand and reduces investment risk for users to the greatest extent. The equipment has the advantages of stable operation, safety and reliability, long service life, convenient operation, compact structure, easy installation, etc. GEP intelligent dual-shaft shredder is your best choice when buying a a two shaft shredder!