1. Metal Detectors

- Function: Metal detectors are devices used to identify the presence of metallic objects, including ferrous (iron-based), non-ferrous (aluminum, copper, etc.), and stainless steel materials. They detect metal through electromagnetic fields or pulse induction technology.

- Working Principle: They generate an electromagnetic field, which interacts with metal objects and produces a signal that alerts users to the presence of metal.

- Applications:

- Food Industry: Detecting metal contaminants in food products to ensure consumer safety.

- Pharmaceuticals: Ensuring that metal particles do not contaminate medicines during production.

- Recycling: Identifying and sorting metals from other materials.

- Security: Screening people and baggage at airports, public venues, and industrial facilities.

- Mining: Locating metal ores and underground metallic objects.

- Advantages:

- Detects a wide range of metals (ferrous, non-ferrous, stainless steel).

- Non-contact and non-destructive detection.

- Suitable for various industries (e.g., food, mining, security).

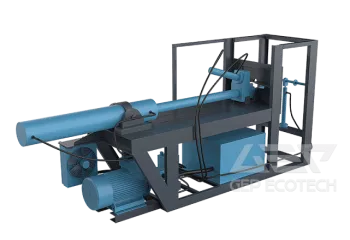

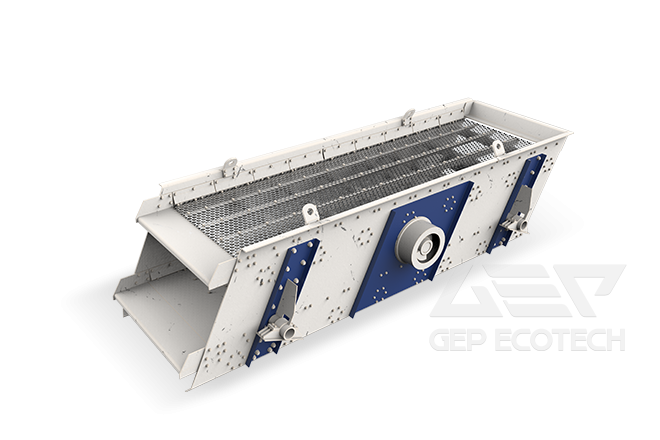

2. Iron Removers (Magnetic Separators)

- Function: Iron removers are devices specifically designed to extract and remove ferrous metal contaminants from raw materials and products using magnetic fields.

- Working Principle: They use permanent magnets or electromagnets to attract and capture ferrous metals from moving material streams.

- Applications:

- Food and Beverage: Removing iron particles from raw materials like grains, spices, and liquids.

- Mining and Quarrying: Extracting ferrous impurities from ores and minerals.

- Recycling: Removing iron-based materials from waste streams.

- Ceramics and Glass: Ensuring iron-free raw materials to prevent defects in final products.

- Chemical Industry: Purifying raw materials by eliminating ferrous contamination.

- Types of Iron Removers:

- Magnetic belts or conveyors

- Magnetic drums

- Magnetic grids and plates

- Magnetic pulleys

- Advantages:

- Efficient for removing large volumes of ferrous contaminants.

- Works continuously with minimal supervision.

- Cost-effective for separating iron in bulk processes.

Summary of Differences:

Feature | Metal Detectors | Iron Removers |

Purpose | Detects all metals (ferrous and non-ferrous) | Removes ferrous metals only |

Technology | Electromagnetic fields or pulse induction | Magnetic fields (permanent or electromagnetic) |

Metal Sensitivity | Detects ferrous, non-ferrous, and stainless steel | Only captures magnetic metals (iron, steel) |

Applications | Detection in food, pharmaceuticals, security | Separation in mining, recycling, and bulk materials |

Output | Provides alerts or signals | Physically removes and collects ferrous material |

Efficiency | Identifies all metal types | Best for bulk ferrous metal removal |

Suggestions for selecting usage

When detecting all metal impurities, especially non-magnetic metals such as aluminum and stainless steel, choose a metal detector.

When removing ferromagnetic impurities, and with a large processing capacity and simple requirements, choose an iron remover.

Combining the two: In high demand production lines, metal detectors and iron removers are usually used in conjunction to ensure comprehensive removal of metal contamination.

In essence, metal detectors are used when you need to find and identify any metal, while iron removers are designed to extract and remove ferrous materials from products and processes.

Please feel free to contact me directly if you need to know the specific model, installation method, or other detailed information!