Paper mills produce waste materials such as ragger wire and light slag in the production process, whose main components are plastic, steel wire and residual paper pulp. These materials are mixed and entangled with each other, forming large objects that are difficult to split and therefore require high shredding performance of the shredder.

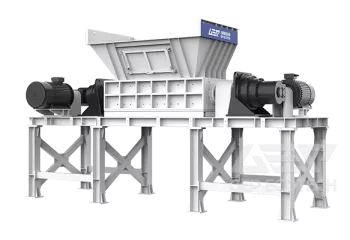

A paper mill in Hunan, China, after many visits and comparisons, finally decided to cooperate with GEP, because of the high shear force and shredding capacity of the GEP's shredder, which capacity can reach 15 tons per hour and the final product size <100mm.