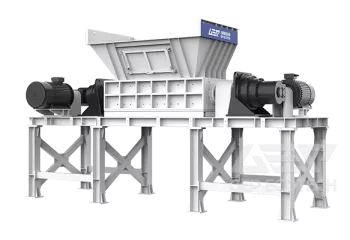

This project sets a new benchmark for a customized aluminum building materials manufacturer in the Middle East. Designed to process 4 tons per hour of various aluminum scrap—including foil, sheets, profiles, and cans—the line ensures high-quality material recovery. The core of the system is the robust Double-Shaft Shredder (Model GD9Q), a powerful Aluminum Shredder and Scrap Metal Shredder for primary size reduction. Supported by a full suite of Metal Recycling Machines for screening, magnetic separation, and eddy current sorting, it delivers purified fragments ready for smelting into new products. The client is highly satisfied, praising the line's exceptional efficiency and output quality.

Home

{{headline}}

Back

{{headline}}