It is Imperative to Deal with Hazardous Waste

Industrial waste is a solid and liquid waste with one or several dangerous characteristics, such as corrosive, toxic, flammable, reactive, or infectious. Generally include: metal, waste acid, waste residue, organic type, which takes up 70-75% of the total amount of hazardous waste. With the development of industry, the increasing amount of hazardous waste discharged from the industrial production process has brought many hidden dangers to production and life..

Application of hazardous waste disposal industry

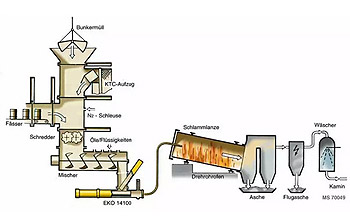

hazardous waste“rotary kiln—exhaust-heat boiler” disposal system

Cement kiln collaborative disposal

SMP (Shred-mix-pump)

Key link - hazardous waste pretreatment

Hazardous waste shredding tower is a set of intelligent,modular and one-stop hazardous waste pre-treatment plan,which is developed by GEP in the light of the characteristics of hazardous waste disposal and its own technological advantages.

The system can not only provide target customers with necessary professional intelligent shredding equipment, but also combine with professional fire companies to design a high quality fire control system to achieve all-round safety control and ensure efficient operation of shredding line.

Technology of GEP intelligent tower type hazardous waste shredding system

Fire-fighting device, Safe!

The configuration of professional firefighting devices not only makes the shredding line more systematic and complete, but also effectively prevents dangerous hazards caused by flammable and explosive nature in the process of hazardous waste crushing.

Intelligent control, Reliable!

Intelligent terminal control makes every detail of equipment running in control. It not only facilitates users to monitor the operation of equipment, but also sends operation data to central control center in time, forming effective early warning mechanism.

Tower type design, Concise!

GEP unique tower design is not only a great place for the installation and regular inspection of the equipment, but also greatly saving the time cost of its later maintenance.

GEP----High-end Professional Shredding

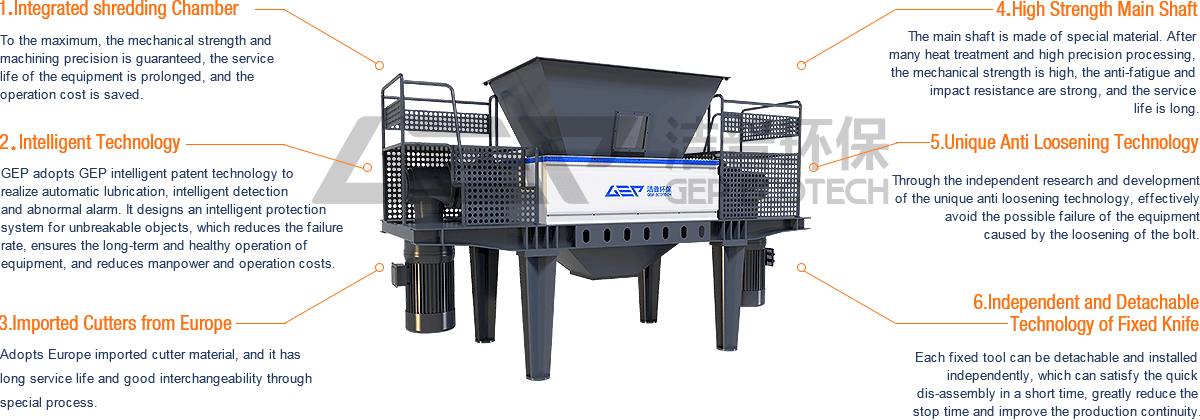

1.Integrated shredding Chamber

To the maximum, the mechanical strength and machining precision is guaranteed, the service life of the equipment is prolonged, and the operation cost is saved.

2.Intelligent Technology

GEP adopts GEP intelligent patent technology to realize automatic lubrication, intelligent detection and abnormal alarm. It designs an intelligent protection system for unbreakable objects, which reduces the failure rate, ensures the long-term and healthy operation of equipment, and reduces manpower and operation costs.

3.Imported Cutters from Europe

Adopts Europe imported cutter material, and it has long service life and good interchangeability through special process.

4.High Strength Main Shaft

The main shaft is made of special material. After many heat treatment and high precision processing, the mechanical strength is high, the anti-fatigue and impact resistance are strong, and the service life is long.

5.Unique Anti Loosening Technology

Through the independent research and development of the unique anti loosening technology, effectively avoid the possible failure of the equipment caused by the loosening of the bolt.

6.Independent and Detachable Technology of Fixed Knife

Each fixed tool can be detachable and installed independently, which can satisfy the quick dis-assembly in a short time, greatly reduce the stop time and improve the production continuity.

GEP ---- Scheme Selection and Customization

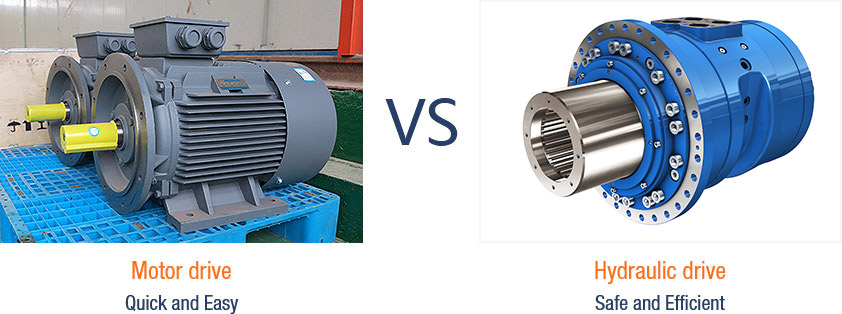

Two Driving Modes

Selection of Production

| Model | GD8 | GD9 | GD10 | GD12 |

| Output | 3t-8t | 5t-9t | 8t-12t | 10t-18t |

GEP -- The Best Service System

Free maintenance within 12 months after delivery

Answer tech inquiry within 30 minutes

Completion of engineer dispatch within 24 hours

Acceptance of service requests all of 365 days of year

GEP is committed to providing customers with the most targeted shredding solutions with a complete and effective service system. From design to site planning, from the installation guide to professional and technical training, based on Internet technology, GEP carries on the establishment of customer intelligence archives perfect service system, realizes the monitoring of 24 hours of remote use of customer equipment and makes the most professional and full range of services to reduce the fault losses to a minimum, so as to make the technology services more convenient and efficient.

GEP -- Extraordinary Strength in the Industry

GEP domestic factories has a CNC machining center with 1 meter, 2 meters, 3 meters, 5 meters, 10 meters CNC machining tools, CNC lathes, precision milling machine, precision drilling machine, precision grinding machine, laser cutting machine, welding machine, tapping machine and other complete machining equipment. All more than 40 units machining equipment can produce all complete parts, matching with advanced heat treatment process; it provides the guarantee for the high precision machining and mass production of the crushers.