Time flies, 2025 is coming to an end. In the wave of deepening the global "carbon peaking and carbon neutrality" strategy and accelerating the upgrading of the solid waste resource utilization track, GEP ECOTECH has successfully concluded its annual journey with technological innovation as the core and project implementation as the starting point. Among them, the successful delivery of the MSW to Alternative Fuel Production Project in the Middle East and the Construction Waste Combustibles to Alternative Fuel Project in Shanghai not only became a benchmark model for regional solid waste resource utilization, but also demonstrated the core value of alternative fuels in breaking the "garbage siege" and promoting energy transformation, drawing a satisfactory conclusion to the annual development.

In the current global consensus of "reducing carbon emissions", alternative fuels (SRF/RDF) have become a key lever for solid waste resource utilization and energy structure optimization. It converts various types of solid waste that originally needed to be buried and incinerated into clean energy that can replace fossil fuels. This not only significantly reduces the environmental pressure of solid waste disposal and greenhouse gas emissions, but also effectively fills the gap in traditional energy, which is in line with the energy transformation and environmental protection policies of various countries. Especially in the fields of collaborative disposal of cement kilns and power generation in power plants, the large-scale application of alternative fuels is promoting the green innovation of "turning waste into treasure" in the industrial sector, becoming an important path for enterprises to practice social responsibility and explore new economic growth points. GEP ECOTECH has been deeply involved in the field of alternative fuel preparation for many years. With refined process design and efficient core equipment, it provides integrated solutions for global customers and helps the industry upgrade to green.

Middle East Benchmark: Refining System for Complex Native Waste, Bag Breaker Builds the First Line of Defense for Efficient Production Capacity

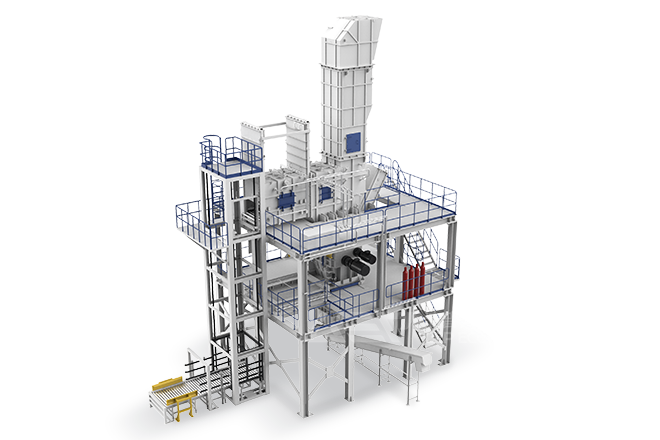

The landing of the 1000 ton daily alternative fuel project in the Middle East is a heavyweight achievement for GEP ECOTECH in 2025. This project serves a well-known local household waste sorting center, aiming to create a specialized alternative fuel preparation system for complex primary urban household waste (including plastics, paper, textiles, organic matter, etc.). With a processing efficiency of 50 tons/hour and a daily working time of 20 hours, it achieves a production capacity breakthrough of 1000 tons/day and ultimately produces high-quality SRF/RDF fuel for collaborative disposal in cement kilns. The efficient operation of the project relies on the hard core empowerment of GEP ECOTECH waste bag breaker.

As the "first level" of native waste disposal, GEP ECOTECH waste bag breaker solves the pain points of complex materials in Middle East projects with four core advantages: the assembled body design is matched with a comprehensive observation door, greatly reducing the difficulty of on-site installation and maintenance, and adapting to the operation and maintenance needs of high temperature environments in the Middle East. Large diameter dynamic knife rotary cutting not only ensures high output, but also effectively avoids entanglement of materials such as plastic bags and textiles, ensuring smooth processes. The precise adaptation design of the front and rear fixed blades allows for flexible adjustment of spacing and spring preload through screws, enabling flexible response to different types of garbage and preventing equipment jamming; The rear fixed blade can prevent material backflow and clean the spindle winding, further improving disposal efficiency. The stable power combination and cooling device, combined with a motor and planetary gearbox, enable the equipment to operate continuously for a long time, laying a solid foundation for subsequent processes such as magnetic separation and iron removal, drum screening and grading.

According to customer feedback, the system accurately achieves efficient conversion of complex materials, ensuring stable fuel quality. The full process automation control significantly reduces operating costs, and the integrated delivery mode shortens the project landing cycle, helping it quickly seize the opportunity in the regional resource utilization market.

Shanghai Model: Precise Focus on Combustible Materials in Construction Waste, Single Shaft Shredder Creates High-Quality Fuel Core

At the same time, the successful delivery of the Construction Waste Combustibles to Alternative Fuel Project in Shanghai has become another benchmark for GEP ECOTECH to deeply cultivate the domestic segmented market. GEP ECOTECH understands the strict requirements of the market for fuel quality (calorific value, moisture content, chlorine content) and supply stability. Therefore, the design of the solution directly addresses the pain points: the bouncing screen and magnetic separator ensure the purity of the feed, the single shaft shredder ensures the particle size and production capacity of the discharge, and the packaging machine optimizes the product form to reduce transportation costs. This project achieves continuous production and low failure rates through streamlined equipment configuration and automated processes, reducing operational difficulties and labor costs. It can quickly respond to the demand for green fuels from cement plants and thermal power plants in Shanghai and surrounding areas, while meeting environmental regulatory requirements and creating clear economic value. The stable output of the project depends on the precise empowerment of the single shaft shredder.

In response to the shredding needs of combustible materials in construction waste, the GEP ECOTECH single shaft shredder demonstrates strong adaptability: the single shaft cutting design is combined with a hydraulic pusher to achieve rapid shredding and significantly increase production capacity; The small square blade adopts a four-way adjustable design, effectively improving material utilization and reducing consumable costs; The high manganese steel material sieve can flexibly adjust the particle size of the discharged material, accurately matching the specifications of alternative fuels, and the multi module combination design is easy to replace and maintain; The intelligent hydraulic system realizes functions such as automatic opening and closing of maintenance doors, auxiliary material pressing, and automatic oil lubrication, greatly improving the level of automation and reducing human dependence.

According to customer feedback, the production line only requires 1-2 workers to complete shift operation and maintenance. The output fuel has stable calorific value and uniform specifications, fully meeting the contract requirements of surrounding cement plants and power plants. It achieves efficient conversion from "garbage" to "commodity", and the investment recovery cycle meets expectations, becoming a secret weapon for enterprises to establish competitiveness in segmented markets.

Step by Step to Thousand Miles: GEP ECOTECH Footprints in 2025

The successful completion of two benchmark projects is a vivid reflection of GEP ECOTECH's technological strength and market reputation in 2025. Looking back at the whole year, GEP ECOTECH has continued to deepen its cultivation in the fields of alternative fuel preparation and solid waste resource disposal, delivering dozens of projects covering scenarios such as household waste, construction waste, and industrial solid waste. Every project is GEP ECOTECH's practice of the concept of "intelligent driving, green future", and also a deep understanding of customers' differentiated needs and the craftsmanship of process solutions.

Looking ahead to 2026, GEP ECOTECH will continue to focus on the solid waste resource utilization track, continuously optimize alternative fuel preparation technology and equipment, and expand its global market layout. On the new journey, GEP ECOTECH looks forward to working together with global customers to transform every waste into new energy driving green development.